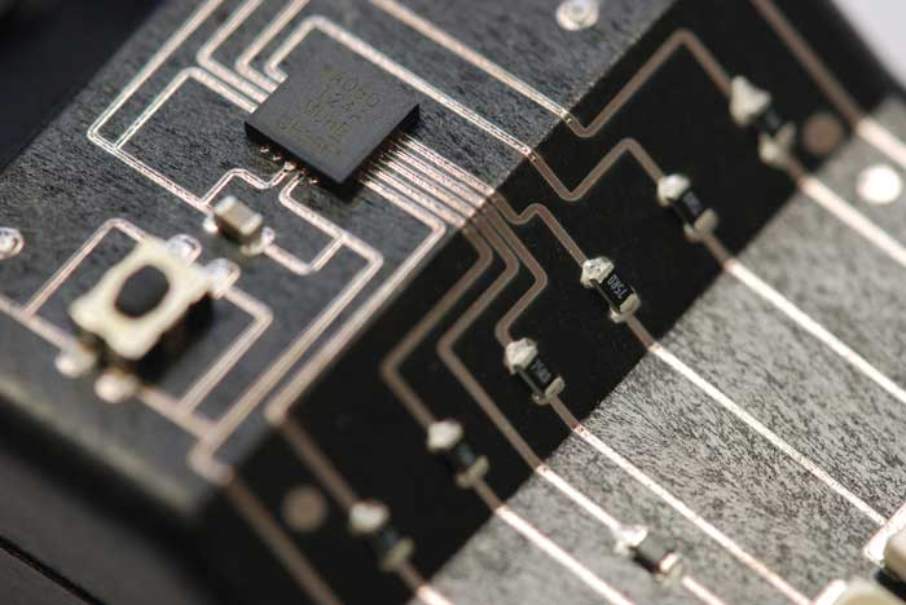

The Nuremberg-based Neotech AMT manufactures technologies for 3D printed electronics and offers production levels and R&D systems in the 3D printing industry. In order to advance additive manufacturing, the company will now focus on two major projects: the EU PENTA project “Hyb-Man” and AMPECS.

As far as the first project is concerned, Neotech AMT will collaborate with 11 partners from Germany and the Netherlands to implement hybrid 3D manufacturing methods that will allow a flexible and instantaneous production of smart systems. The new hybrid aims at taking advantage of 3D Printing of polymers in combination with 3D printed electronics as core production technologies.

“The outcome of the project will be improved Additive Manufacturing processes, a hybrid manufacturing production cell and prototypes of integrated electrical products (LEDs, automotive adaptive sensors) made using the hybrid manufacturing cell.”

As for the second project, it lays emphasis on the printing of ceramic substrates. Funded by EU Manunet Program, researchers will develop 3D printable ceramic materials to create the structural body and incorporate printed electronics onto this component. End use applications will be automotive, aerospace as well as mobile communications.

Speaking about the two new projects, Dr. Martin Hedges, Managing Director of Neotech explains:

“We have been working on combining 3D Printed Electronics with classical 3D Printing of mechanical structures and these new projects will accelerate the development. The ability to use fully Additive Manufacture to create complete 3D mechatronic systems enables many novel applications across diverse industries. The resultant process lines will address the needs for low volume agile manufacture within a single platform.”

Thanks to these two new projects, Neotech AMT is on the right track to expand additive manufacturing and provide new solutions regarding the creation of electronic devices.