The company will accelerate the development and commercialisation of both the M1 and MetalXL solutions

MX3D has just secured € 2,25 million from DOEN Participaties, PDENH and the Netherlands Enterprise Agency (RVO).

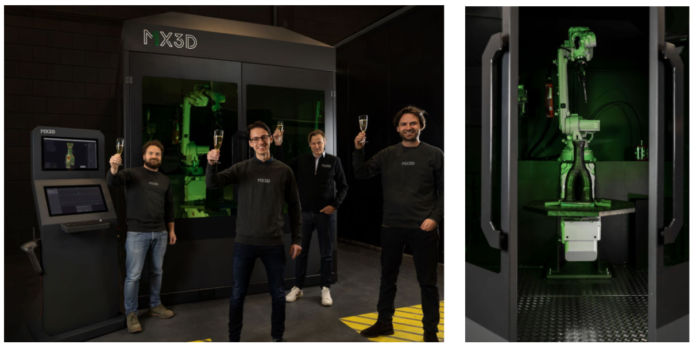

The Dutch Robotic 3D metal printing company first aims to accelerate the go-to-market capabilities of its M1, a complete robotic metal AM system that includesa welding robot, software and control system.

The announcement follows the first feedback of tests on a series of 3D-printed structural steel connectors performed with Takenaka.

MX3D demonstrates its capabilities within the AM industry after the 3D printed stainless steel bridge it constructed in Amsterdam. Over time, it has built up extensive expertise in robotic wire arc additive manufacturing (WAAM) which provides several benefits for high impact industries like Oil & Gas, Maritime and Tooling.

Today the company has developed a package that includes welding robot, software and control system to 3D print metal parts in-house.

Known among beta customers, its MetalXL solution combines software and a control system, that turn existing welding robots into industrial grade 3D metal printers. The new investment will therefore also support the commercialization of this technology.

“Our Metal XL Software and Control System enables companies to turn their welding robot into a high end 3D metal printer, in the course of one day”, says Gijs van der Velden, CEO of MX3D. “Since the launch of MetalXL we have received many customer requests whether we could supply them with a complete solution. The M1 metal AM System is the answer to this call. Now customers without a welding robot can quickly and affordably start printing large metal parts.”

Moving forward with the development of MetalXL, the manufacturer ambitions to connect

multiple brands of robots, power sources and sensors together and services this way over

80 percent of the worldwide robotic market.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com