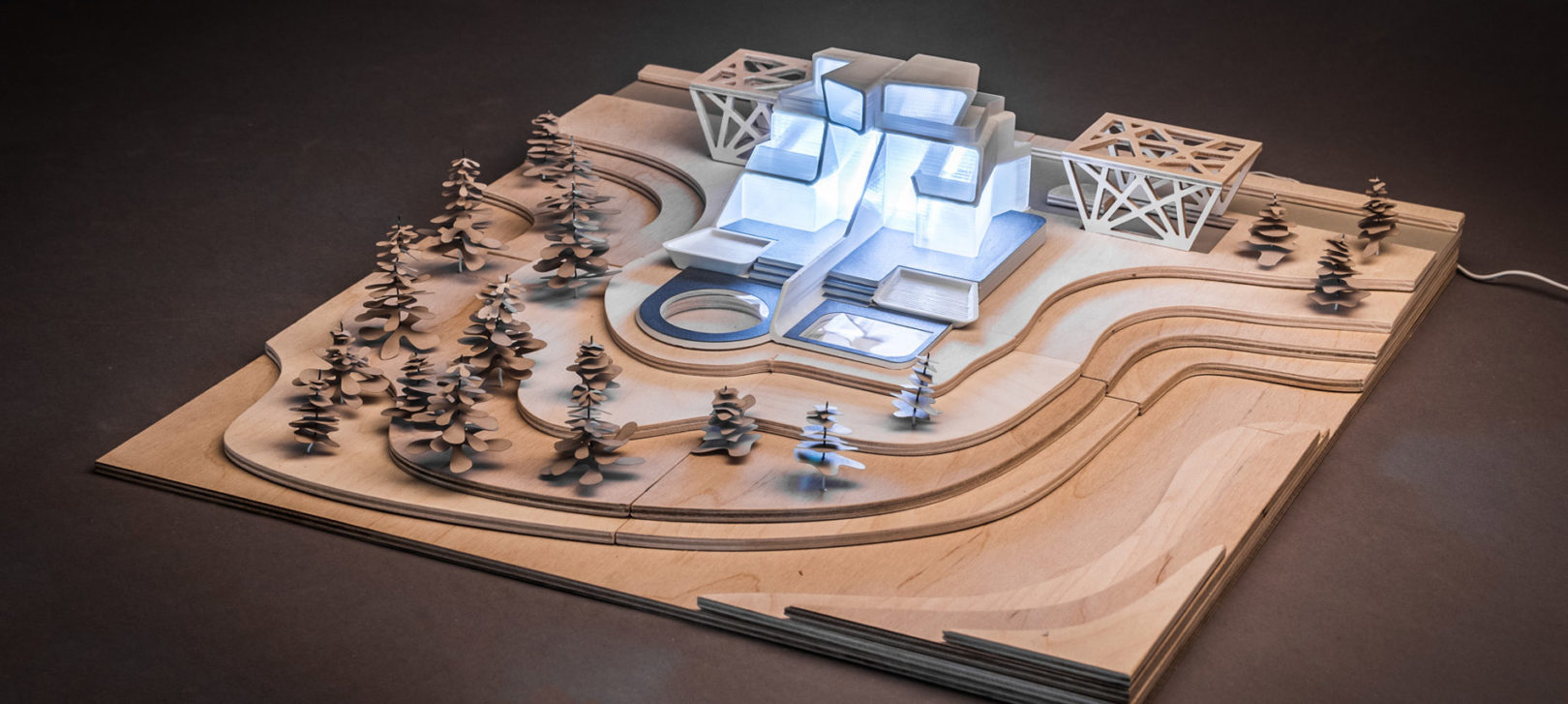

Architecture design is one of those sectors that benefit the most from 3D Printing. Designer Paula Szarejko demonstrates it by creating a multi-material architectural model both nice and useful.

Desktop 3D printing, CNC, and laser combined in one stunning multi-material architectural model.

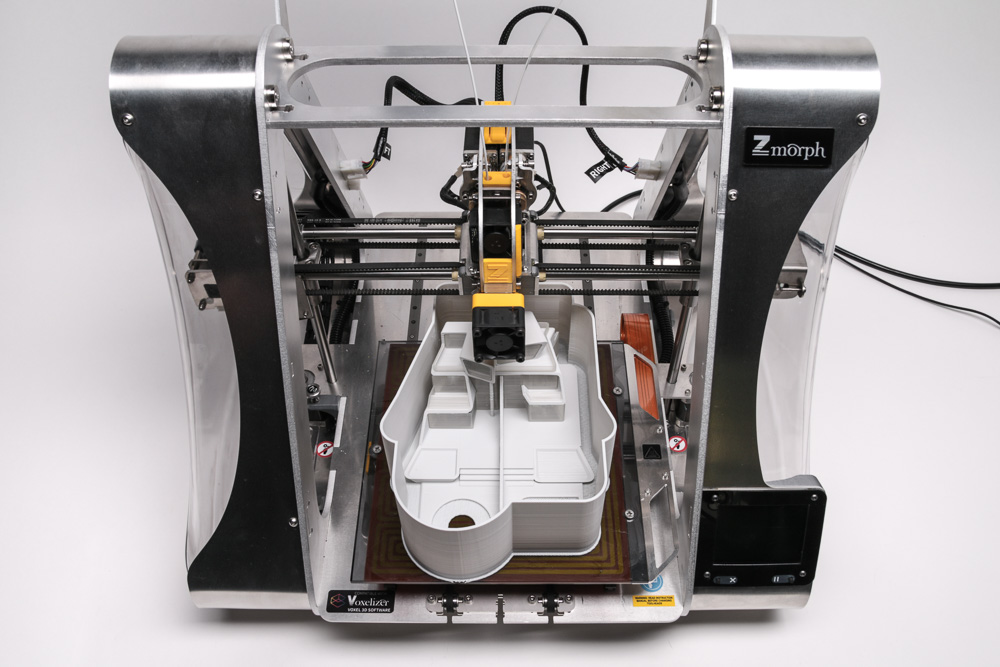

Even in 3D printing, the maker has to choose the best tool to overcome the limitations he might meet in his/her work.  Thanks to the desktop mini-factory, it was possible to mix single and multi-material 3D printing, CNC milling, laser cutting, and engraving.

Thanks to the desktop mini-factory, it was possible to mix single and multi-material 3D printing, CNC milling, laser cutting, and engraving.

After designing the futuristic house and its surroundings, Paula Szarejko chose the needed materials and manufacturing technologies from ZMorph 2.0 SX interchangeable toolheads. That’s why, instead of 3D printing the whole landform, she CNC-cut it in plywood to get more organic and natural feel. Furthermore, with a laser, she cut in a paper trees of the model.

To 3D print the building, another part of the architectural model, Paula S. made use of DUAL PRO extruder. Gray PLA was used for walls while translucent PLA imitates glass. ZMorph 2.0 SX avoided her to prepare separate files to print this object in parts before assembling the set hence time and cost-saving.

The house was printed in one part that took the entire worktable, while the land was cut in parts and assembled together into a scaled representation four times bigger than ZMorph’s working space.

Multitool 3D printers allow architects to quickly design, prototype and physically reveal their ideas. Last, according to the expert, this project also proves that professionals using desktop machines like ZMorph 2.0 SX aren’t limited by its workspace.

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});