Since I was a little kid, I was into remote controlled models and always wanted to own some by myself. And as a grown up, I’ve bought my first models and had a lot of fun with them but I wanted more. 4 Years ago, I bought my first 3D printer and after a while I got used to it and started to create my own stuff. I worked on my very first unique design of a rc model and printed it. Like you can see in the pictures below, the first one is the conceptual drawing and the second one the printed parts.

To be honest, it never worked like I wanted it to work so I gave up after a while.

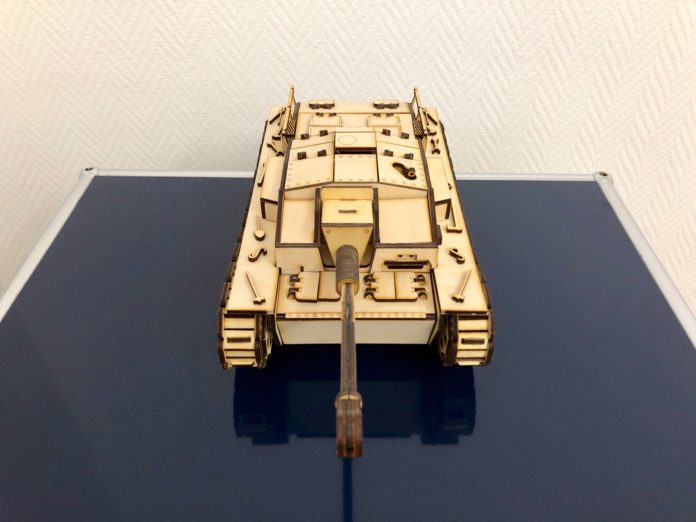

But at the time I got into laser cutting I came back to functional models and also to rc models out of laser cutted plywood. I was downloading plans from ready to cut models like this tank.

After I gained some more experience I started to create my own remote vehicles and machines again. A huge inspiration what I could create came from my son. He loves cranes and so I began to draw one using CorelDraw and Fusion 360. It took me some hours to get a hang of it but at the end I was happy with the result:

For me it was important that I’m able to cut most of the parts out of 3 mm plywood. I designed it to fit for that and only got some 3D printed parts and of course some screws and electronics. The first prototype was designed to be glued together but I’ve learned the lesson and because of instability I redesigned it for no glue and all screw.

At some point of creating the crane I wanted to build my own remote control as well and started to learn alot about arduino and motor controlling. So I designed my own PCB for the remote control. In the next pictures you see the steps from drawing the PCB in Autodesk Eagle to building a prototyping platform and finally to order the PCB’s.

In the whole process of cutting out the countless pieces of plywood I was in close contact with George (CEO of endurance lasers) and we talked about visiting the Maker Faire in berlin together. He with his lasers and Me with my rc crane. So we shared a booth together and I got my first Maker Faire experience, which was pretty awesome. Here are some Pictures of the booth.

And yes, after one day of soldering and putting everything together, the crane moved and was able to pick up things.

All the discussions and impressions for the maker faire, and also some really nice interviews leaded me to start with a new project. But I wanted to make things better and don’t make the same mistakes I made with my crane. I decided to build a scaled remote controlled excavator.

As I want to scale things right and get also some details Im planning it big.

Here you can see some photos.

Like the rc crane before, most of the parts will be laser cutted out of 3mm plywood. There will also be a special system which memes the hydraulics. As I’m planning to release the plans for the public afterwards I want it to be doable for small money. A plug and play hydraulic cylinder at this size (300mm upwards) will cost up to 200 euro. So I designed my own system which is using a geared dc motor. Compared to the plug and play system, the costs for one cylinder will be around 40 euros instead of 200.

The arm prototype is already cutted out and has a length of about 90 cm.

If you all want to follow my process of building stuff like that just follow my “Blog” like facebook page. https://www.facebook.com/Fizzle-bastelt-111487110222616/

I’m always happy about feedback and new impressions or recommendations. Currently I try to get the excavator ready for my next visit at the Maker Faire in Berlin and my first Visit at the main Maker Faire in germany in Hannover next year. Maybe see you there.

Learn more about Endurance 10 watt laser here

Follow Endurance’s community on Twitter

Contact us if you have any questions:

skype: george.fomitchev

+1.239.302.0053

+7.916.225.4302 (Whatsapp, viber)