MetShape, a manufacturer of indirectly 3D printed metallic components, has supported the research work of CIC nanoGUNE – the Basque Nanoscience Cooperative Research Center – by 3D printing a high-precision virus model. According to the startup, they resolution they achieved would not be possible with other metal AM processes.

Fresh reminder, MetShape has recently secured seed financing from AM Ventures. At the heart of its applications, we find the Lithography-based Metal Manufacturing (LMM) Technology developed by Incus GmbH.

For the first application the company unveils publicly today, the team works on the production of aerosols. In a press release, they explain that these are virus-laden solid or solid/liquid particles that travel in the air. A precise understanding of virus aerosols is essential in order to identify the transmission mechanisms of viruses, such as SARS-CoV-2 or influenza, and to develop solutions for prevention.

This type of viruses constitutes the main topic of research from the team at CIC nanoGUNE. For their research project, the scientists need virus models that are as detailed, small and precise as possible.

NanoGUNE works with nanoscale molecular aggregates, but increasingly uses water / virus models on the centimeter scale to complement wetting and dewetting studies on the nanoscale.

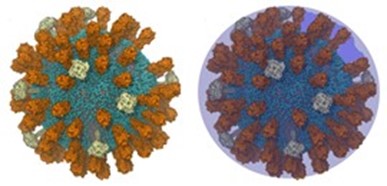

Figure 1 shows the model of an influenza virus with a diameter of ca. 120 nm. Its surface consists of up to 500 so-called “spikes”, which – unlike on CoV – are only about 10 nm apart, such that tiny capillaries are located between the spikes. Liquid aerosols lose water very quickly in air, they quasi dry up, which, on the one hand, can deactivate viruses. On the other hand, the loss of mass means a longer residence time in the air. This fine balance determines the transmission. Do the capillaries play any role?

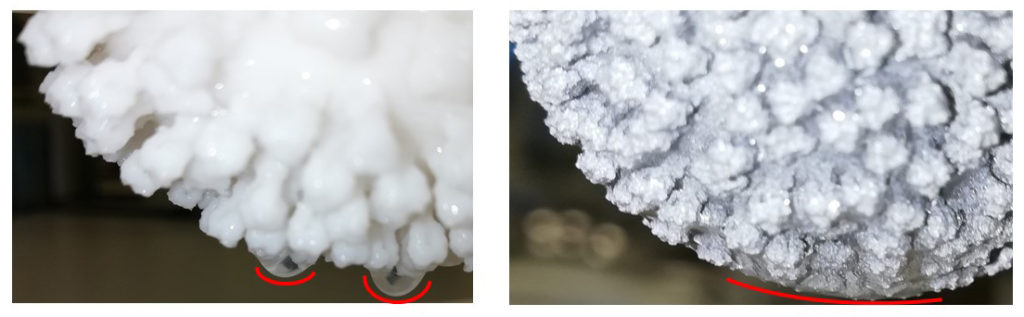

For the centimeter-sized model, the capillaries must be less than 1 mm in size, otherwise gravity will falsify the result. Such precision cannot be achieved for microparts with conventional 3D printing processes, such as BJ or SLM. With this problem, nanoGUNE contacted MetShape, who offer top precision and resolution for complex components.

The MetShape team has therefore 3D printed a high-precision virus model on the scale 250000:1. This means that the model has a diameter of approximately 30 mm. A debinding and a sintering processes follow the printing process.

Compared to a standard polymer model (see Figure 2), The metal model performs significantly better due to the lower mass of the water, based on the smaller size of the model. Both models were hydrophilized with an adhesive spray. In the case of the polymer model, however, the resulting large water mass causes droplet artefacts, while the metal model is correctly wetted.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com