One of the key takeaways from Formnext 2022 was the growing number of robotic solutions for Additive Manufacturing. We even foresaw that the upcoming months will see a lot more of AM-dedicated developments in this sense. A new partnership between Meltio and 12 software companies is here to prove that we may be on the right track for this trend. Through this partnership, the wire-laser metal 3D printing technology manufacturer aims to establish an ecosystem that will industrialize its metal additive manufacturing process.

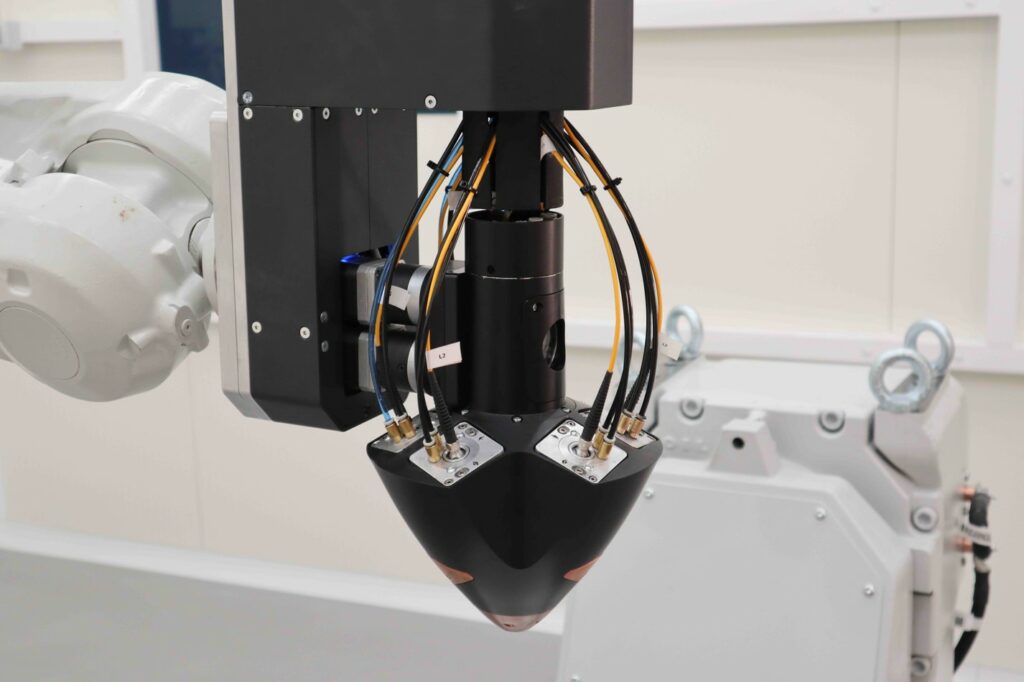

To do so, the Meltio Engine Software Partners ecosystem will identify a set of software solutions that could be used with Meltio Engine CNC Integration and Meltio Engine Robot Integration – and allow the generation of 5 Axis G-Codes.

The software companies include: SKM DCAM by SKM Informatik; AdaOne by Adaxis; AiSync by AiBuild; Esprit by Hexagon; Fusion 360 by Autodesk; Aplus+Mastercam by Camufacturing and Mastercam; Hypermill by OpenMind; SiemensNX by Siemens; Hy5CAM by 1ATechnologies; RobotStudio 3D Printing PowerPack by ABB and SprutCAM X by SprutCam.

Ángel Llavero, CEO of Meltio explains: “For a year we have been working with all of them sharing the needs that we understood most suitable for our customers, going as far as sharing as well as in some cases sharing the mathematical algorithms needed for the functionalities we required. The result of this collaboration between our engineers and the teams of these companies has now resulted in offering this software platform to the market.”

“With this alliance, Meltio sends the message to all [users] of the Meltio Engine CNC and Robot Integration that the software that appears is tested and certified for the handling and proper use of Meltio’s technology.”

The open platform for hardware (any robot or CNC) and software

The new platform would enable the use of any software to manufacture metal parts while meeting the demand for hybrid and robotic additive manufacturing processes.

In this vein, a process for validating technically each solution has been created, avoiding this way extra work between the final customer and every software provider. These extra tasks may be for instance, defining post-processors, ensuring that the specific software can get the most out of the Meltio Engine or the possibility to use two materials in the same part (Dual-Wire).

Meltio’s engineers have studied the technical requirements for developing the slicing strategies for the majority of the parts that the industry requires . They have defined 9 levels of complexity, including example geometries that represent help customers as well as developers understand the diversity of parts, the company explains.

Meltio’s engineers have studied the technical requirements for developing the slicing strategies for the majority of the parts that the industry requires . They have defined 9 levels of complexity, including example geometries that represent help customers as well as developers understand the diversity of parts, the company explains.

To facilitate the work of engineers and designers, the platform is equipped with a number of advanced slicing features: fixed tool orientation, revolved surfaces, features on non-planar surfaces, simple surface coating , radial cladding, 360 features, variable layer deposition, controlled area repair and non-controlled area repair.

This announcement follows the recent launch of a toolpath generator software and a new laser calibration system; and marks another step forward to enhance the user experience of the company’s wire laser metal 3D printing technology in software and hardware.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com