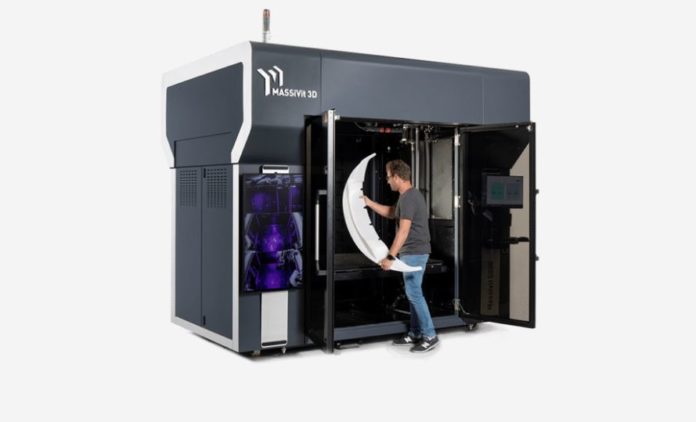

Provider of large-scale 3D printing systems, Massivit increases the range of applications that can meet flammability-related safety and performance, as well as translucency requirements, with new materials in its portfolio: Dimengel 20-FR (DIM 20-FR) and Dimengel 300 (DIM 300).

Flame retardant materials are gaining momentum. So far, a lot of them have been made available for prototyping and production series. Massivit’s new line of materials stand out from the crowd as they enable to achieve very large 3D printed parts across industries.

Key specifications of each material

DIM 20-FR is a photo polymeric gel that have been recognized through the UL Blue Card Program. The compliance with the UL94-V0, a standard for flame-retardant materials, ensures that Massivit 5000 operators can produce flame-retardant applications with the security that the material has been tested, and continues to be monitored at regular intervals by UL (Underwriters Laboratories).

The new material can be processed on the recently unveiled large-scale 3D printer, the Massivit 5000, and supports a wide range of post processing options including composite materials reinforcement that are increasingly used by automotive, rail, and military manufacturers to achieve stiff, complex production parts.

DIM 300 on the other hand, supports applications that focus on translucency. The material can meet the needs of industries that are looking to achieve prototypes, design verification, interior design, architecture, scenic displays, and a range of advertising applications.

5 proprietary print materials are currently available in Massivit’s portfolio: DIM 90, DIM 100, DIM 110, DIM 20-FR™, and DIM 300 – all of them help support requirements in terms of production speed, size, definition, fidelity, flame retardancy, translucency, or illumination.

“Dimengel lies at the heart of Massivit 3D’s patented Gel Dispensing Printing technology” says Erez Zimerman, CEO at Massivit 3D. “We are continuously developing new, innovative materials to broaden the scope of applications available to our customers, whether for the purpose of manufacturing railway spare parts, automotive aftermarket parts, or amusement park displays.

In addition, it is of utmost importance to ensure our materials and technology meet industry regulations, particularly regarding safety. The new UL94-V0 certification responds to customer requests and growing industry demand for flame-retardant parts and models.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com