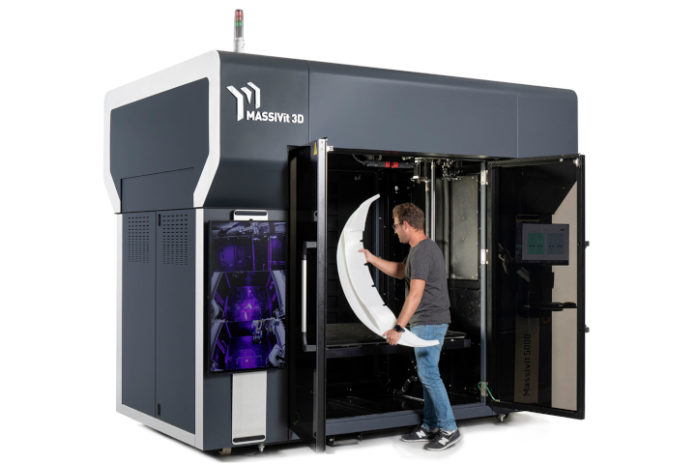

Massivit 3D Printing Technologies has added the Massivit 5000 to its portfolio of industrial arge-scale 3D printing systems.

According to the 3D printer manufacturer, would expedite lead times for manufacturing large parts, prototypes, and tooling by up to 30 times the production speed of existing technologies.

Based on the company’s unique, patented Gel Dispensing Printing (GDP) technology – the new Massivit 5000 introduces to the market new resolutions, materials, and automation capabilities that address industry 4.0 needs, enabling production of large-scale parts within hours instead of weeks.

The new machine comes along with a new printing material, DIMENGEL 110, designed to facilitate high- definition printing and greater fidelity to CAD designs. Two new resolutions enable print optimization according to layer thickness and speed requirements. The Massivit 5000 offers a Dual Material System that allows operators to print simultaneously with a different material on each head. New software automation features also allow operators to improve workflow efficiencies and enable easy monitoring and operations.

This latest addition to the Massivit 3D portfolio of large-scale 3D printers facilitates complex, large parts up to 145cm x 111cm x 180cm (57” x 44” x 70”) that instantly cure during the printing process, enabling ready-made parts straight off the printer without the need for post-processing and with almost no required support structures.

Erez Zimerman, CEO at Massivit 3D, said “We are thrilled to bring to market this new additive manufacturing system that will empower manufacturers to overcome existing limitations in production speed, size, and complexity. It is a significant milestone on our roadmap towards transforming manufacturing of large parts across multiple industries.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com