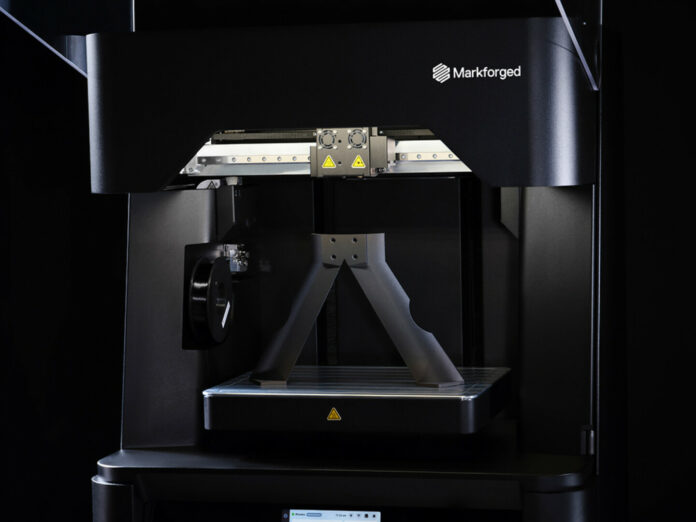

Markforged has been making strides in the Additive Manufacturing segment with 3D printers suitable for the factory floor. The FX10 is a next-gen composite 3D printing solution for robust parts. It is the logical follow-up to the X7 Industrial Series printer from the manufacturer.

The X7 Industrial Series Printer has been deployed in several factories globally to facilitate high ROI and strong parts. The FX10 is fitted with a fifth-gen modular composite system and is highly automated, fast, and big. It’s twice as fast as the X7 with precise accuracy at high printing speeds.

The Markforged FX10 can reach up to 60℃ and has a 375mm x 300mm x 300mm build volume. According to the manufacturer, it can facilitate a user-friendly printing experience with its simple interface. The automated features such as machine calibration and spool changeover for continuous printing add to the ease of use.

The FX10 uses a patented CFR (continuous fiber replacement) process resulting in strong composite parts that can replace machined metals. The modular print system has quick-swappable elements for added material compatibility.

Check out the previous version of Markforged FX20 3D printers.

A laser micrometer is incorporated to scan various parts during machine calibration & 3D printing. The stored data is then interpreted via the company’sinspection software for quality assurance & dimensional validation.

Irrespective of the operator, automated machine & pre-print calibration models offer consistent print quality.

Perks of using FX10 in manufacturing

Printing critical parts on the factory floor becomes seamless in a dynamic large-scale manufacturing environment. It removes the dependence on obtaining machined parts produced using traditional manufacturing methods.

3D printing reduces the holding costs of inventory. It enables responsiveness to line down events. Part designs can be stored in Markforged’s cloud-based Eiger™ software to print when required. The FX10 integrates with factory MIS and other business systems.

Factory productivity can be significantly improved while operating costs are kept down. Industrial 3D printing with composite materials helps produce parts with accuracy and repeatability that are missing in plastic 3D printers.

Factories are thus future-proofed with modular print architecture. FX10 is built by considering the upgradeability factor. The vision module will be introduced later to determine printer health and performance using detailed images of the calibration parts.

Author: Nagarjun M

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.