Users of Mantle’s hybrid manufacturing machines can reduce print times for tool inserts by up to 20% while improving surface finish on downfacing surfaces.

This toolpathing strategy can be implemented via the company’s Automated Toolmaking System. With this software update, users of TrueShape can undercut in molds, sliders, and other complex tools. This enhancement allows manufacturers to create tooling components that go directly to molding with even fewer post-processing requirements, further reducing lead times and labor costs.

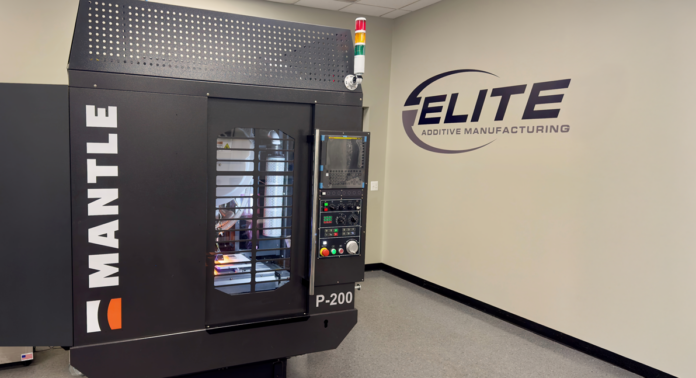

“Implementing Mantle’s Automated Toolmaking System has been transformative for our operations at Elite Mold,” said Paul Patrash, CEO of Elite Mold & Engineering. “The technology has enabled us to significantly increase our production capacity while simultaneously reducing lead times for our customers. One of the most substantial benefits has been the dramatic reduction in our reliance on sinker EDM machines, which has streamlined our workflow and improved our operational efficiency. With this latest software update delivering up to 20% faster printing speeds, we can produce precision tooling even more quickly than before, further expanding the overall capacity of our toolroom. In today’s competitive manufacturing environment, Mantle’s technology provides us with a critical edge that directly translates to better service for our clients.”

Injection molders and moldmakers have not only implemented Mantle’s solution to enhance their internal toolmaking operations but have also expanded their business models to offer Mantle as a service. Injection molders Elite Mold & Engineering, Four Square/TRE, along with injection moldmaker Buss Precision Mold, now provide their customers with access to Mantle’s automated toolmaking system, allowing a broader range of manufacturers to benefit from faster lead times, superior surface finishes, and reduced costs.

The system accelerates product development and reduces time-to-market by expediting the delivery of First-out-of-Tool (FOT) parts. Manufacturers often reduce tooling lead times by over 50%, resulting in substantial cost savings compared to conventional methods.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com