$5.8 million contract, two years and machine learning: those key words are at the heart of the agreement between Lockheed Martin and the Office of Naval Research. The aim of this collaboration is to optimize 3D printing of complex parts so that the manufacturing process could become more independent.

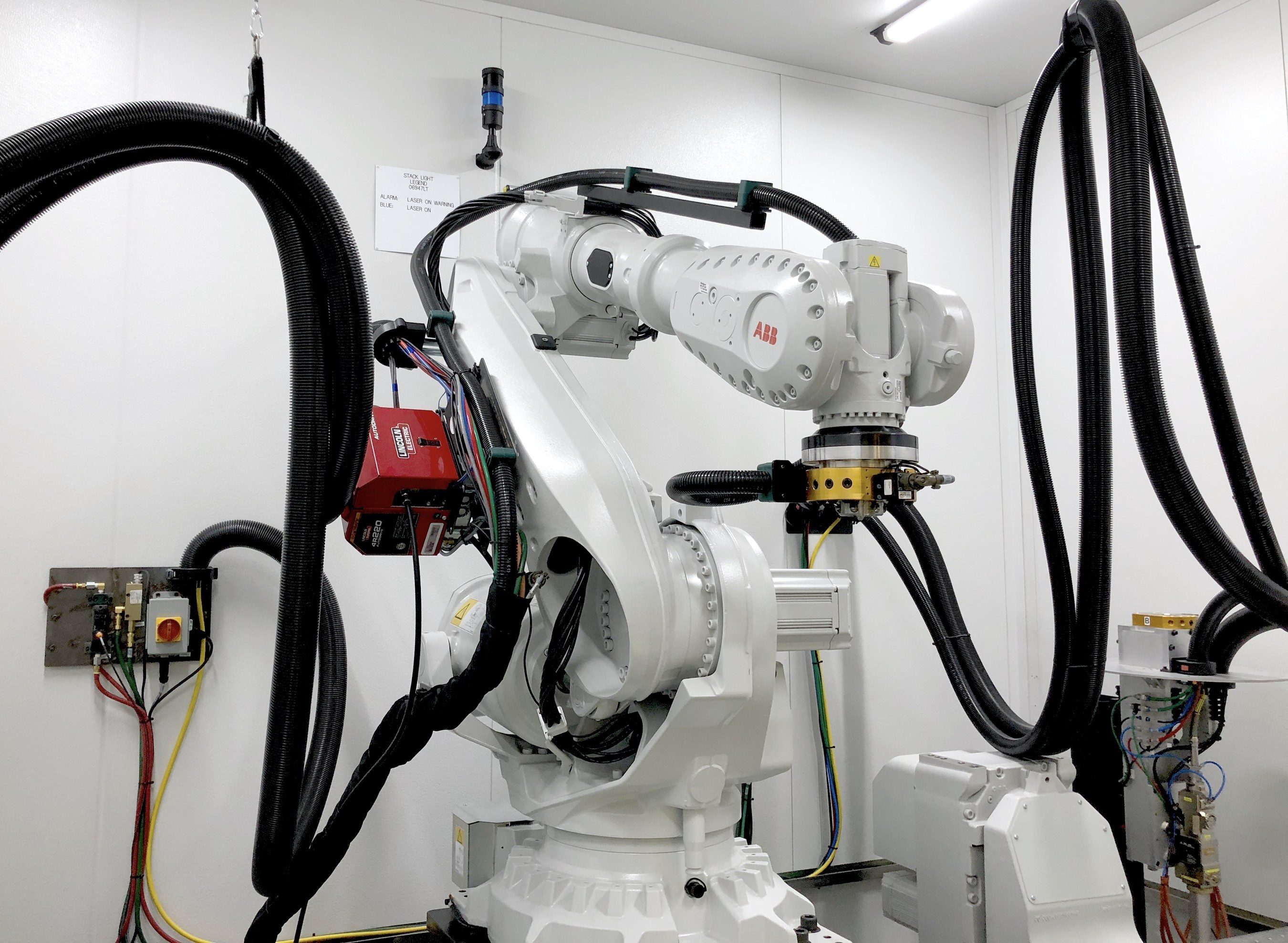

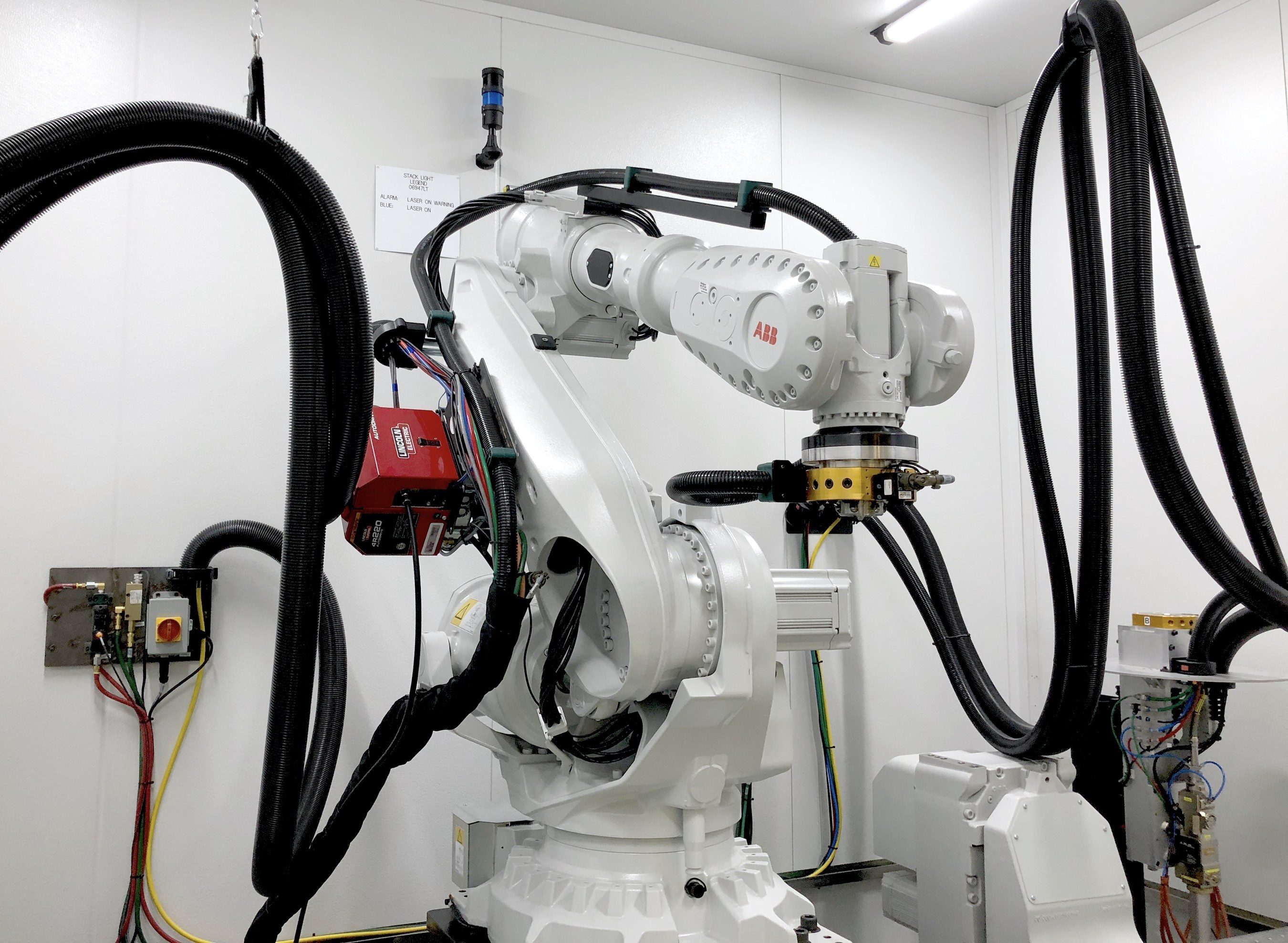

The truth is complex components often require constant monitoring by expert specialists to get them right. Furthermore, if any one section of a part is below par, it can render the whole part unusable. That’s why, Lockheed Martin’s researchers will explore possibilities given by mchine learning. They will create software models and sensor modifications so that the robots can build better parts.

“We will research ways machines can observe, learn and make decisions by themselves to make better parts that are more consistent, which is crucial as 3-D printed parts become more and more common,” said Brian Griffith, Lockheed Martin’s project manager. “Machines should monitor and make adjustments on their own during printing to ensure that they create the right material properties during production.”

Applying machine learning techniques to additive manufacturing

“When you can trust a robotic system to make a quality part, that opens the door to who can build usable parts and where you build them,” said Zach Loftus, Lockheed Martin Fellow for additive manufacturing. “Think about sustainment and how a maintainer can print a replacement part at sea, or a mechanic print a replacement part for a truck deep in the desert. This takes 3-D printing to the next, big step of deployment.”

Now, hours are spent to build testing quality after fabrication on the one hand; on the other hand, a component might be built to compensate for the weakest section for a part and enable more margin and mass in the rest of the structure. The aim of Lockheed Martin is therefore to enable machines to make decisions about how to optimize structures based on previously verified analysis.

In order to achieve that, performance attributes of the machine parameters, microstructures and material properties will be thoroughly measured in order to comply with a robot system.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter

Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});