Lawrence Livermore National Laboratory (LLNL) brings a novel approach to 3D printing with microwave technology. Microwave Volumetric Additive Manufacturing (MVAM) is a technique that enables the use of a wide range of materials.

MVAM enhances microwave energy usage to cure one’s material by allowing for broad-based selections of opaque and composite materials with high printing speed and accuracy.

For the first time, LLNL researchers have demonstrated that microwave energy can propagate much more deeply into materials than conventional light-based techniques, allowing both opaque and translucent epoxy resins to be quickly cured. It enables parts to be made on a larger scale and geometrically complicated than is possible today with state-of-the-art 3D printing.

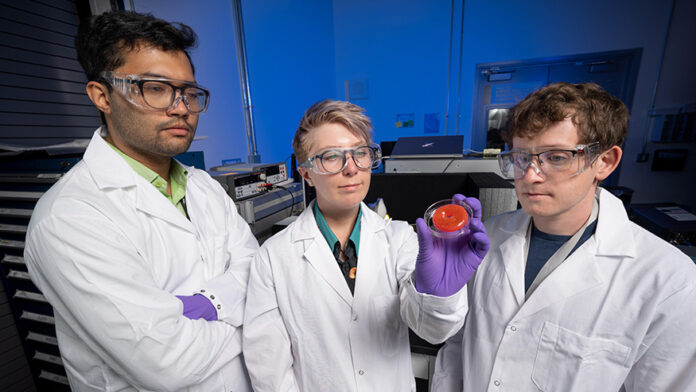

As per LLNL research scientist Saptarshi Mukherjee, “I think this will revolutionize how people look at Additive Manufacturing. If we think about more applications — aerospace, automotive, nuclear industry — their geometries are simple, large & need rapid prototyping. One major impact [of MVAM] is if we can maintain a feedstock of materials surrounded with a microwave antenna array, we can now think about creating simple & complicated large geometries at scale using microwaves.”

They then made a computational model for the microwave curing process for system design. It helps to optimize the curing period & power delivery for enhanced thermal control while printing.

The research team validated their device using a proof-of-concept experimental model where current hardware cured materials in 2.5 minutes by functioning at 40 watts & the odd thing is the team predicts that it can be reduced to six seconds using robust systems.

This can be applied to industries, like aerospace, automotive, and healthcare as a part of manufacturing difficult parts, with better strength and thermal resistance properties. The LLNL remains working on this technology to reduce its cost and increase the scale of its applications.

Co-principal investigator Schwartz expressed “A whole new world of printing materials becomes possible. With the unique opportunity to expand the definition of ‘printable,’ accessing chemistries was previously impossible in light-based systems. This is a whole new printing space & our ongoing progress is extremely exciting.”

You can read the entire research here.

Author: Nagarjun M

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.