Materials producer Liqcreate has released a new engineering grade 3D-printing resin: Composite-X.

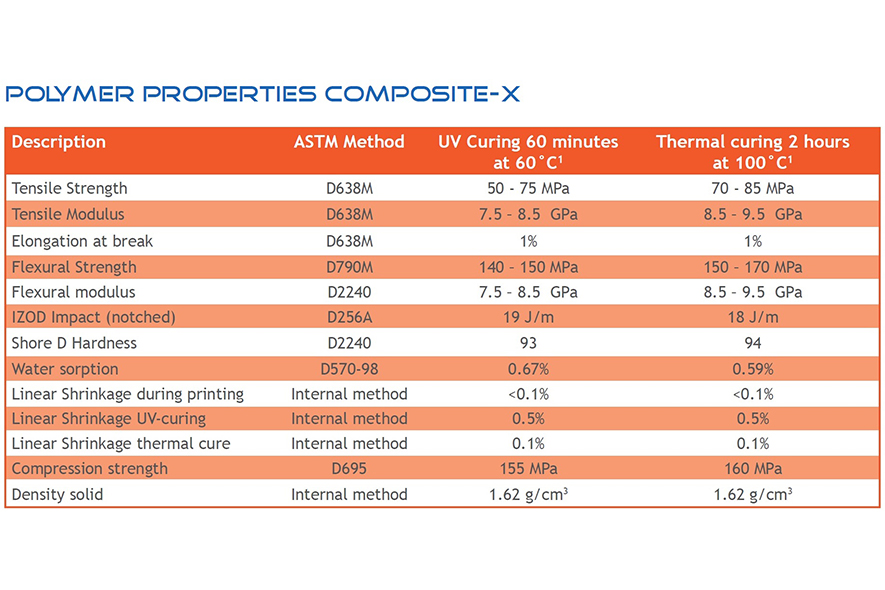

With a flexural modulus of over 9000 MPa, the ceramic-infused resin would be stiffer still once cured, which makes it a good candidate for heavy-duty automotive and aerospace components.

The Netherlands-based company understands that applications have their own requirements which are often not met by ‘off-the-shelf’ resins. That’s why, it has dedicated it core business to customized resin development. Its portfolio of engineering resins includes flexible materials (Flexible-X), strong resins (Strong-X), extremely impact resistant resin (Tough-X) or even clear resins (Clear Impact); all of them being compatible with a wide range of liquid-based 3D printers such as Asiga, Atum3D, Formlabs as well as entry-level MSLA, DLP and SLA 3D-printers.

Key features of the Composite-X material

Described as one of the stiffest and strongest materials available in the market, the material can be processed in the range of 385 – 420nm. It can be used after UV-post curing, or the properties can be boosted with a thermal cure.

It delivers excellent chemical resistance, high strength and high stiffness which makes it ideal for wind tunnel testing, under the hood applications and heavy duty industrial applications. Manufacturers who need to deliver Chemical resistant parts, Wind tunnel testing, rapid tooling for manufacturing, fluid flow components, abrasion resistant parts, automotive components, or even fixturing can see a great potential in the material.

Nano Reinforced Composite-X

Low shrinkage Composite-X

High performance Composite-x

Composite-X is currently available in 1,5kg and 375 gram bottles.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com