Netherlands-based 3D printing resin manufacturer Liqcreate has added a new ESD safe 3D-printing resin its photopolymer resin portfolio: Liqcreate ESD.

As the name implies, the opaque black photopolymer resin can serve for the fabrication of 3D-printed parts that exhibit electrostatic discharge properties needed for electronic manufacturing and parts for ESD-safe workplaces (EPA). Liqcreate ESD can be used on open DLP, LCD and SLA 3D-printers in the range of 385 – 420nm. Open resin 3D-printers in the range of 385 – 420 nm using DLP, MSLA, SLA or LCD technology are most compatible with the new material.

Due to the isotropic electrostatic dissipative properties, it is suitable for electronic devices and components that require ESD. Using this material, operators can increase manufacturing capabilities by printing custom jigs, fixtures and tools to protect critical electronics components from static discharge.

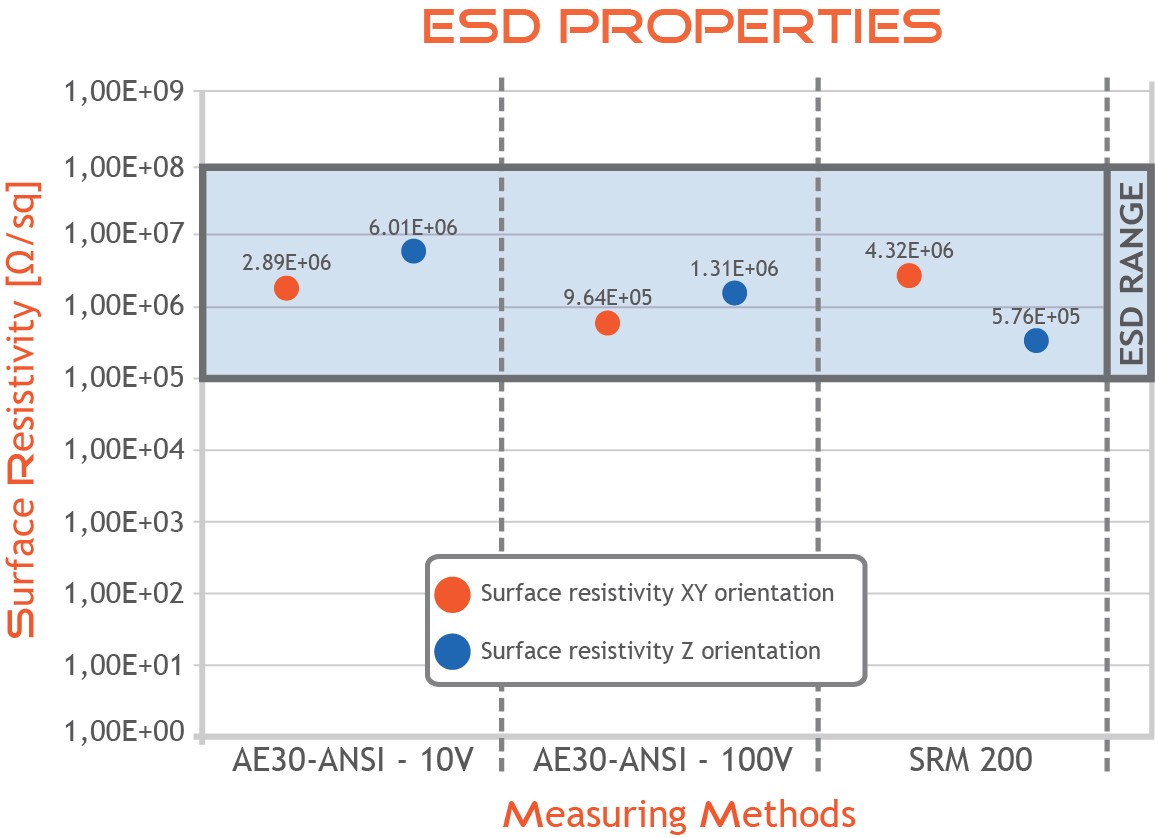

Isotropic ESD properties

The ESD properties were measured by different methods and in two printing directions. AE30-ANSI and SRM 200 measurements on surface resistivity show uniform ESD properties across the part and in different directions. All these values remain well within the ESD range.

OEM possibilities for ESD resins & masterbatches

Next to its branded resin range, Liqcreate also offers to develop custom materials for those in need of a non-standard formula for a specific application. Through this OEM service, customers can request the development of a 3D-printing resin with precise characteristics, which impact its print speed and color, as well as the properties of resulting parts.

When it comes to ESD resins, clients can request the formulation of materials with different properties. Think about elastomer or flexible ESD materials with a Shore A ranging from 45 to 95. Or high temperature ESD materials that can endure chip manufacturing cycles at elevated temperature. Once customers have started a custom material development project, Liqcreate’s engineers work to develop a resin according to their specifications, and provide guidance on how to dial in their new resins for a given printer, preparing them for production.

You may find here other materials that are part of Liqcreate’s portfolio.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com