Following the announcement of its plant in Maisach, EOS announces the upcoming availability of three polymers for Additive Manufacturing (AM) from ALM, a subsidiary of the EOS Group that focuses on providing customized material solutions for the AM market. Already used in North America, these materials will be available in Europe as from March 2018 onwards: Carbon fiber-reinforced polyamide 11 material (ALM HP 11-30), the flame-retardant polyamide 11 (ALM FR-106), the polyamide 12 material filled with hollow glass microspheres and carbon fibers (ALM PA 640-GSL).

These materials will open up new application areas for industrial 3D printing. Dr. Tobias Abeln, Chief Technical Officer (CTO) at EOS explains: “As of February 2018, ALM received its formal ISO 9001:2015 certification that specifies the requirements for a quality management in organizations.”

ALM HP 11-30

The carbon fibers give this material high strength, impact resistance, and an increased elongation at break for a fiber reinforced material. ALM HP 11-30 suits the best for components subject to mechanical wear that require a minimum level of toughness. Automotive industry applications, motorsport for instance, can exploit its potential.

ALM FR-106

The flame-retardant polyamide 11 combines both toughness and good strength. It is an ideal solution in the aerospace industry and also meets rigorous FAR 25.853 aviation standards. Furthermore, the material is convenient for applications in which outstanding flame-retardant properties and thin wall thicknesses are an advantage (housings, casings or hard-wearing fasteners).

Main characteristics include its well-balanced properties and good detail resolution.

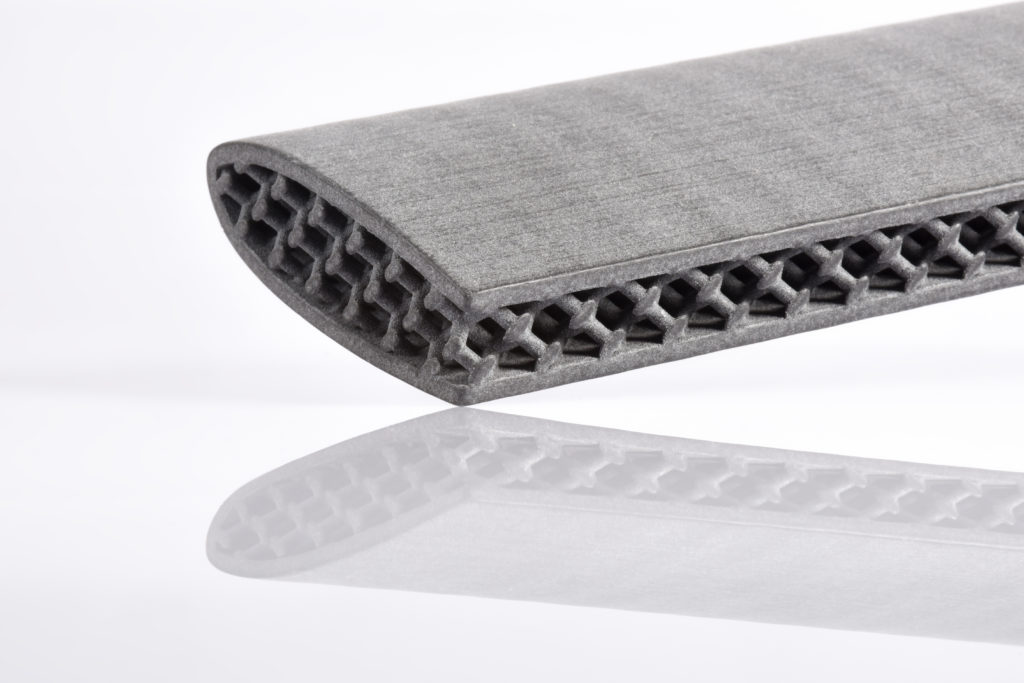

ALM PA 640-GSL

This material almost provides the same properties as a normal glass filled polyamide, but with substantially reduced weight (component density: 0.82g/cm³). With its microsphere and carbon fiber filling, ALM PA 640-GSL is particularly suitable for applications that require extremely low weight, high strength, and rigidity in one product. At the same time, ALM PA 640-GSL features increased thermal resistance and excellent surface quality. Application fields include the aerospace, shipping, sports, model making, and motorsport sectors. The material’s enhanced thermal stability also makes it suitable for applications in which components are exposed to high temperatures.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});