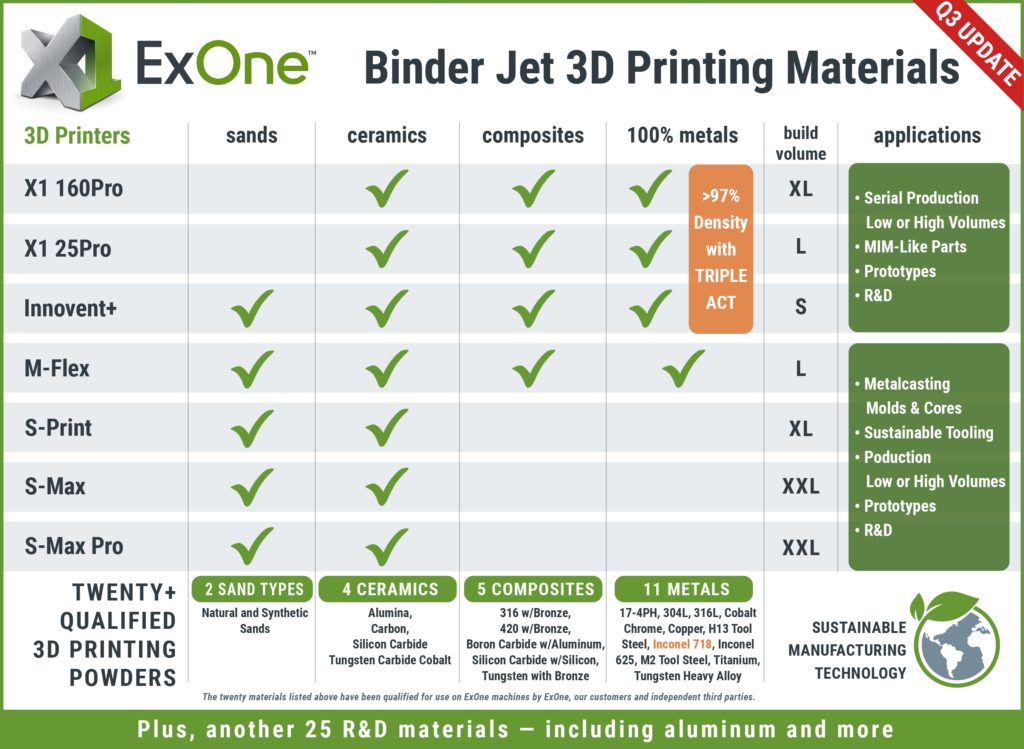

Early at the beginning of the year, ExOne unveiled an aggressive strategy to make the widest range of materials available for its binder jetting technology. 21 materials including single-alloy metals, ceramics and composite materials, had then been qualified for the company’s technology, whereas aluminum and Inconel 718 had only been qualified for 3D printing in controlled research and development environments.

Today, the company has confirmed the qualification of Inconel 718 for its binder jetting technology. “ExOne can now transition R&D materials to full qualification as demand increases,”said Rick Lucas, ExOne CTO and VP, New Markets.

Inconel 718 enables applications in the aerospace, energy and automotive industries. The manufacturer said it is known for its high strength and hardness. It can withstand corrosion as well as chemicals and extreme temperatures ranging from sub-zero to 1300° F hence its applications for high-temperature applications. Its welding characteristics make it suitable for jet engines and tooling, or corrosive environments, such as those featuring seawater or acids.

“Today’s qualification of Inconel 718, following on the heels of M2 Tool Steel earlier this year, shows the ExOne R&D team is aggressively delivering new materials for binder jet 3D printing,” said Lucas. “Our increasing pace of material qualifications is a testament to the strength of our new metal 3D printer systems equipped with Triple ACT, an advanced compaction technology that is essential for binder jetting metals and other materials at high speeds and densities.”

As is the case with Inconel 718, ExOne’s patented Triple ACT enables 3D printing of standard MIM powders, followed by standard sintering profiles and heat treatments, that deliver high-density results consistent with wrought material. Independent testing verifies that Inconel 718 3D printed and sintered by ExOne meets ASTM standard B637-18.

Remember, you can post AM job opportunities for free on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com