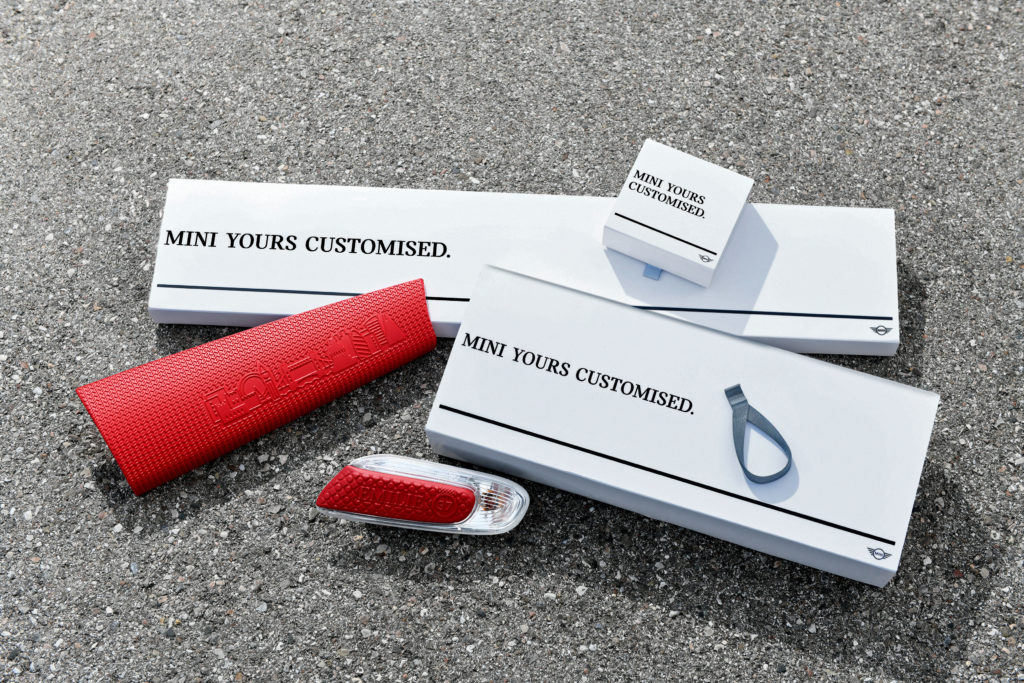

British automotive manufacturer MINI will launch a new customization service for its clients in 2018. Called “MINI Yours Customised”, this program will allow customers to customize their MINI vehicles using 3D printing and laser lettering.

The product range will include the indicator inlays known as side scuttles, trims for the passenger side in the interior, LED door sills and LED door projectors.

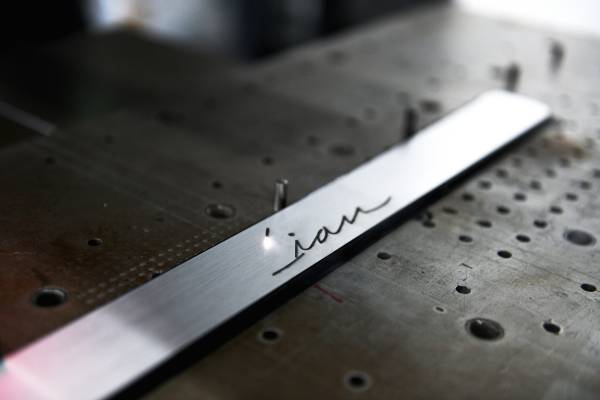

Simply put, once the upgrade parts available in the program are selected, designed and ordered, the products will thereafter be manufactured using 3D printing and laser lettering. Thanks to these technologies, it is possible to meet every requirement of the customer. Furthermore, the designed parts can be implemented by the customer himself/herself or by the MINI service partner. This ensures that if the vehicle is sold later the individualised components can be exchanged. Is is also possible for the customer to modify the selected design when he/she needs something new.

MINI, committed to individualisation, digitalisation and 3D printing

It must be said that, the manufacturer takes advantage of the 3D printing technology by customizing the production of individual products in large numbers for the MINI Yours Customised package.

Configuration is carried out in an Online Shop dedicated to the new product range.

In order to offer this service, BMW Group signed commercial agreements to use 3D printers of Hewlett-Packard Inc., Carbon Inc. and EOS GmbH.

Lastly, a range of different colours, patterns and icons from the individual design worlds is also available for designing the illuminated door sills and the LED door projectors. These design features can be supplemented by text that can be freely formulated in a dedicated field. This provides an unlimited number of different versions that can be created from combinations of colours, patterns, icons and lettering to create a personal signature expressing the attitude, individual interests and lifestyle of the MINI driver.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});