In the list of examples of regenerative medicine treatments that doctors explore to regrow, repair or replace damaged or diseased cells, organs or tissues, we mostly hear about stem cell injections, platelet rich plasma (PRP), prolotherapy, and cartilage regeneration techniques.

A research team from KU Leuven has just made us discover that it could be possible to regrow teeth from the root; at least they are one-step closer to this possibility and 3D printing is a key tool in their process.

The whole research started with one observation: dental conditions such as caries, trauma and developmental anomalies frequently affect the developing permanent teeth, leading to tissue or even whole tooth loss. The roots of immature teeth with pulp necrosis fail to develop and are left functionally compromised on the long-term due to arrested dentin formation.

To address this issue, dental tissue engineering is being considered as a solution for dentin-pulp complex repair/regeneration, and eventually tooth replacement through the fabrication of bioengineered tooth-root.

Given the fact that they provide a temporary 3D structures to support cellular attachment, migration, proliferation, and guided differentiation, scaffolds remain a pivotal item in any tissue engineering solution, assuming that they are biocompatible, and mimic the extracellular matrix (ECM). They should also deliver inter-connected porosity and given the fact that they are custom-made, their mechanical properties should allow surgical handling, biodegradability and promote appropriate cell behaviour for the patient.

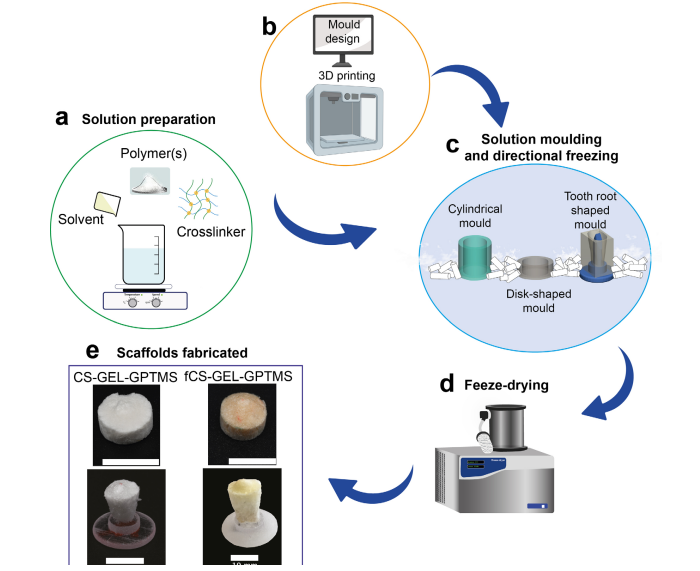

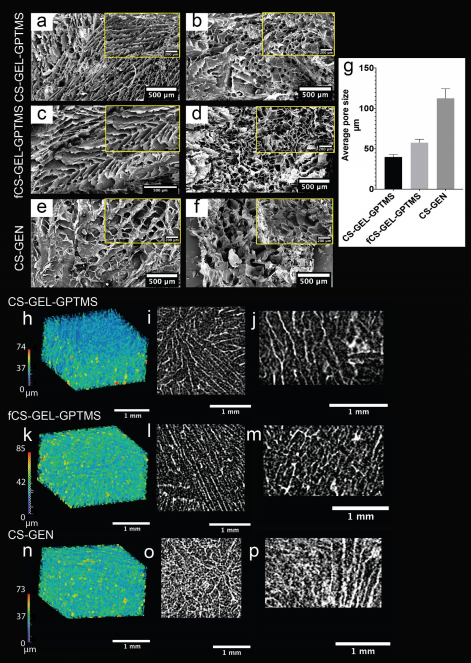

In this specific case, the report explains that researchers “focused on the fabrication and characterization of customized scaffolds made of chitosan from different sources and cross-linkers for dental root tissue engineering. The chitosan scaffolds were prepared by means of emulsion freeze-drying using 3D-printed moulds. While at this stage moulds of basic geometries have been applied, it can easily be appreciated how patient/tooth specific moulds and subsequently also scaffolds can be fabricated based on low-dose cone beam computed tomography (CBCT) imaging (EzEldeen et al., 2017) and inserted, for example, in the wide canals of immature teeth or bony defects for the delivery of bioactive molecules or stem cells.”

Combining CAD and 3D printing for the fabrication of chitosan scaffolds

Chitosan comes in part from the exoskeleton of crustaceans such as crabs and shrimps, fungi, or insects. The experimentation required two types of chitosan: animal origin and fungal chitosan.

The use of fungal driven chitosan was explored for its desirable properties of reduced risk of allergic reaction, low molecular weight and enhanced antimicrobial properties.

Researchers used gelatine powder as an additional polymer, and genipin and 3-glycidyloxypropyl trimethoxysilane (GPTMS) as cross-linking agents.

The chitosan-based scaffolds were obtained via an emulsion freeze-drying technique which involved the design of suitably-sized molds using CAD software. A polyjet 3D printer thereafter 3D printed the CAD file. After their preparation, the polymer solutions were dispensed in the molds before being immediately placed in dry ice for directional freezing to achieve a radially oriented pore structure.

The moulds were then freeze-dried for 24 hours and demolded to obtain the final scaffolds. While basic molds were printed this time around, 3D printing allows for the design and production of patient and tooth-specific molds, and therefore scaffolds.

Further work will focus on obtaining a deeper understanding of stem-cell and immune-cell behaviour in response to the scaffolds to optimize their application in dento-alveolar tissue engineering. The whole report has been published in the eCM Journal.

It’s only been four years ago that consulting firm IDTechEX predicts that the regenerative medicine market would reach $1.8 billion by 2027. In the meantime, several companies invested in the field, either by acquiring startups or by developing 3D bioprinters that could give live to tangible use cases in the field. For now, most bio applications that we cover in regenerative medicine are still at the research level. It would certainly require some more time before we see them on a real patient, and when we will do, we will remember how it started.

Featured image: bioinformant – Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com