MIT researchers have developed a method for 3D printing materials with tunable mechanical properties, which can sense how they are moving and interacting with the environment. The researchers create these sensing structures using just one material and a single run on a 3D printer.

To accomplish this, the researchers began with 3D-printed lattice materials and incorporated networks of air-filled channels into the structure during the printing process. By measuring how the pressure changes within these channels when the structure is squeezed, bent, or stretched, engineers can receive feedback on how the material is moving.

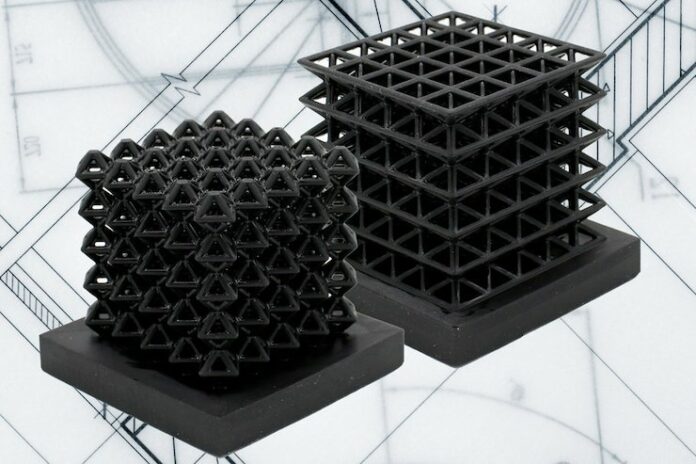

These lattice materials are composed of single cells in a repeating pattern. Changing the size or shape of the cells alters the material’s mechanical properties, such as its stiffness or hardness. For instance, a denser network of cells makes a stiffer structure.

This technique could someday be used to create flexible soft robots with embedded sensors that enable the robots to understand their posture and movements. It might also be used to produce wearable smart devices that provide feedback on how a person is moving or interacting with their environment.

“The idea with this work is that we can take any material that can be 3D-printed and have a simple way to route channels throughout it so we can get sensorization with structure. And if you use really complex materials, then you can have motion, perception, and structure all in one,” says co-lead author Lillian Chin, a graduate student in the MIT Computer Science and Artificial Intelligence Laboratory (CSAIL).

Focus on architected materials

While architected materials can exhibit unique properties, integrating sensors is notoriously challenging. Engineers typically must place sensors on the outside, which is tough because the lattice is full of holes so there is little material to work with. Also, when sensors are placed on the outside, they are not fully integrated with the material and can be affected by noise that comes from a soft material’s movements.

Instead, Chin and her collaborators used 3D printing to incorporate air-filled channels directly into the struts that form the lattice. When the structure is moved or squeezed, those channels deform and the volume of air inside changes. The researchers can measure the corresponding change in pressure with an off-the-shelf pressure sensor, which gives feedback on how the material is deforming.

Because they are incorporated into the material, these “fluidic sensors” are more accurate than sensors placed on the outside of a structure.

“If you stretch out a rubber band, it takes a little time to come back into place. But since we are using air and the deformations are relatively stable, we don’t get these same time-varying properties. The information that comes out of our sensor is a lot cleaner,” Chin says.

“Sensorizing” structures

The researchers incorporate channels into the structure using digital light processing 3D printing. In this method, the structure is drawn out of a pool of resin and hardened into a precise shape using projected light. An image is projected onto the wet resin and areas struck by the light are cured.

But as the process continues, the sticky resin tends to drip and get stuck inside the channels. The researchers had to work quickly to remove excess resin before it was cured, using a mix of pressurized air, vacuum, and intricate cleaning.

They used this process to create several lattice structures and demonstrated how the air-filled channels generated clear feedback when the structures were squeezed and bent.

Building off these results, they also incorporated sensors into a new class of materials developed for motorized soft robots known as handed shearing auxetics, or HSAs. HSAs can be twisted and stretched simultaneously, which enables them to be used as effective soft robotic actuators. But they are difficult to “sensorize” because of their complex forms.

They 3D printed an HSA soft robot capable of several movements, including bending, twisting, and elongating. They ran the robot through a series of movements for more than 18 hours and used the sensor data to train a neural network that could accurately predict the robot’s motion.

Chin was impressed by the results — the fluidic sensors were so accurate she had difficulty distinguishing between the signals the researchers sent to the motors and the data that came back from the sensors.

“Materials scientists have been working hard to optimize architected materials for functionality. This seems like a simple, yet really powerful idea to connect what those researchers have been doing with this realm of perception. As soon as we add sensing, then roboticists like me can come in and use this as an active material, not just a passive one,” she says.

In the future, the researchers look forward to finding new applications for this technique, such as creating novel human-machine interfaces or soft devices that have sensing capabilities within the internal structure. Chin is also interested in utilizing machine learning to push the boundaries of tactile sensing for robotics.

The paper is published today in Science Advances.

Remember, you can post jobopportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com