The micro-AM coating solutions provider Horizon Microtechnologies has been commercializing its suite of in-house coating processes used for microstructures and now they are gearing up to showcase their portfolio at Formnext 2023.

Horizon Microtechnologies will be there at Formnext 2023 along with the micro AM platform developer Boston Micro Fabrication (BMF) on stand B38 in Hall 11.1.

Formnext, one of the biggest events in the 3D printing industry that draws over 800 companies and 20,000 visitors will be held in Frankfurt between November 7 to November 10.

Key characteristics of micro-AM coating solutions of Horizon

The micro-AM coating processes of Horizon Microtechnologies make microstructures more functional. The company achieves this by adding non-metallic conductive and environmentally resistant metallic coatings to polymer micro-AM parts.

With this feature, the micro-AM company is enhancing the applications of additive manufacturing to a wide range of sectors which was earlier out of reach of the AM industry because of restricted 3D printing material options. This in turn reduced the functionality of 3D printed parts.

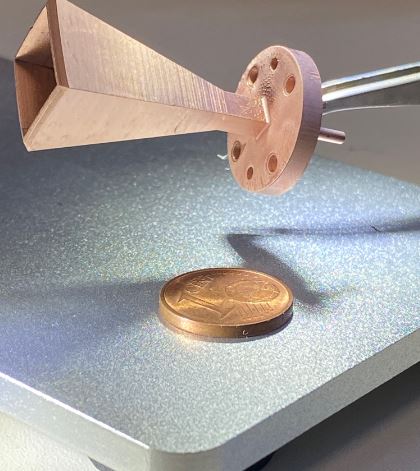

The metallic copper coatings developed by the company are of 1-2 micron thickness which is suitable for a wide range of applications. They also cost internal channels and undercuts to a certain extent as the aspect ratio is a limiting factor more than the length of the channel.

Horizon Microtechnologies aims to facilitate the adoption of micro-AM across various sectors, specially those unreachable earlier and for this the company is working with BMF as their micro-AM platforms are suitable for both prototypes and end products. The company precisely bought a microArch S240 micro AM machine which will speed up the development of its post-build coating technologies. With this, Horizon Microtechnologies can push the boundaries of precision, accuracy and resolution in AM technology. The company thinks this will help in promoting miniaturisation as micro-AM parts find wider applications.

BMF’s S240 micro AM machine employs the projection micro stereolithography (PµSL) process which has been patented. This process takes advantage of digital light processing (DLP) and stereolithography, a flash of light triggering the rapid photo-polymerisation of an entire layer of resin to create micro-AM parts.

Through continuous exposure, the build speed is increased to build up the components from the top down in a resin basin. This reduces the reliance on support structures in 3D printing technology, thereby streamlining the micro-AM workflow.

Speaking about their presence at Formnext 2023, the CEO of Horizon Microtechnologies Andreas Frölich said that customers will benefit from their “vertically integrated solution” which stands by them from “design to delivery”.

“We will have parts on the booth which show the versatility of our coating processes, and the intricate parts that can be made on the microArch S240. Horizon can act as an end-to-end product development and contract manufacturing partner, influencing the design of micro AM parts to optimise them for end-use functionality and also optimise them for the application of our proprietary coating technologies. We can wholly or selectively coat micro-AM parts with a non-metallic conductive layer, add environmental resistance to parts enabling the creation of microscale devices that are more durable, reliable, and better suited for use in harsh environments — such as in the presence of aggressive chemicals and/or high temperatures, and can wholly or selectively coat micro-AM parts with copper”, said Frölich.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com