HBD Metal 3D Printer, a machine manufacturer headquartered in China, has recently closed $60 million Series A financing. This round of financing was led by Qianhai FOF, co-invested by Grand Flight Investment and CITIC Securities Investment, and Winsoul Capital served as the exclusive financial advisor.

By the end of 2021, HBD had delivered more than five hundred metal 3D printing systems in total, which were sold to over twenty countries and regions around the world, ranking among the top in sales.

The core team of HBD has nearly 20 years of experience in laser and metal additive production, of which R&D personnel account for over half of the company’s total number of people, and the R&D investment is as high as millions of US dollars every year. At present, the company has beyond 200 patents, including three international patents, and the number of core technology patents for metal 3D printing systems is industry-leading. In addition, as a main drafter, HBD participated in the formulation of fourteen standards such as national standards and industry standards, and took part in the construction and standard formulation of China’s 3D printing evaluation system.

The company is acknowledged for its expertise in LACM – Laser Additive & Cutting Manufacturing hybrid processing technology, which solves the world-class problem of finishing the inner surface of 3D printed metal parts.

While breaking through the technical bottleneck of products, in order to ensure product quality and service quality, HBD has gradually completed the construction of automated production lines and factories. HBD is highly valued by the Shanghai Lingang New Area Government, and acquired nearly 6.5 acres of land in 2021, planning to build a new R&D and production base. The base will have a built-up area of nearly 60,000 square meters, adjacent to well-known companies such as Tesla Gigafactory 3. With the completion of this financing, HBD will continue to invest in high-tech R&D, technical team building and high-end manufacturing.

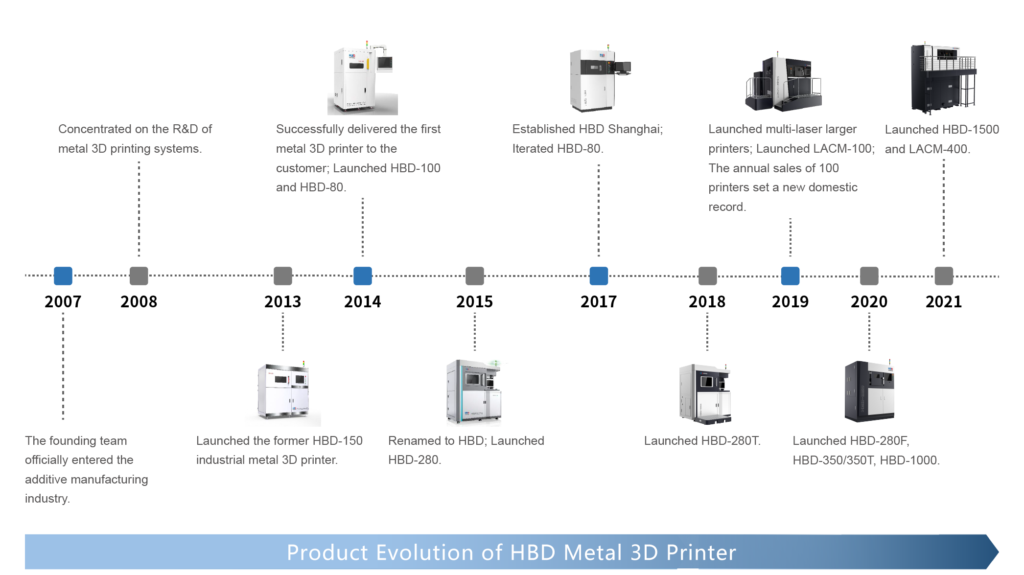

Today, HBD has successfully developed a total of 23 models of large, medium and small machines. The product matrix is complete. HBD cooperates and serves thousands of customers, including CISRI, WeNext, United Imaging, Fosun, Gree, Matsui, Sunshine Laser & Technology and other industry leaders.

As a high-tech-intensive industry, the innovation and development of aerospace is a comprehensive reflection of a country’s manufacturing strength and the modernization level of the defense industry. HBD has been recognized by industry users for its outstanding laser beam quality, optimized air duct structure design, stable and reliable printing accuracy, excellent printing structure design and process development. Multi-laser metal 3D printers such as HBD-1000 and HBD-1500 have been successfully developed and installed in batches. These large-scale equipment have solved many pain points in aerospace manufacturing, and have been stably supplied to numerous top scientific research institutes and aerospace companies in batches.

The nuclear reactor heat exchanger 3D printed by HBD for the nuclear power plant caused a sensation. It changes the traditional heat exchanger from a height of exceeding ten meters to a height of merely 400mm, which not only reduces the volume and weight, but also achieves an amazing order of magnitude optimization in terms of energy efficiency, production cycle and cost. It brings new possibilities for the future aerospace and green energy industries.

At the same time, HBD takes intelligence, automation and digitalization as the starting point to provide enterprise-level integrated high-quality metal 3D printing solutions of “intelligent production line + batch manufacturing + industrial intelligent IoT”, providing customers with more efficient and more flexible new business forms of cooperation.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com