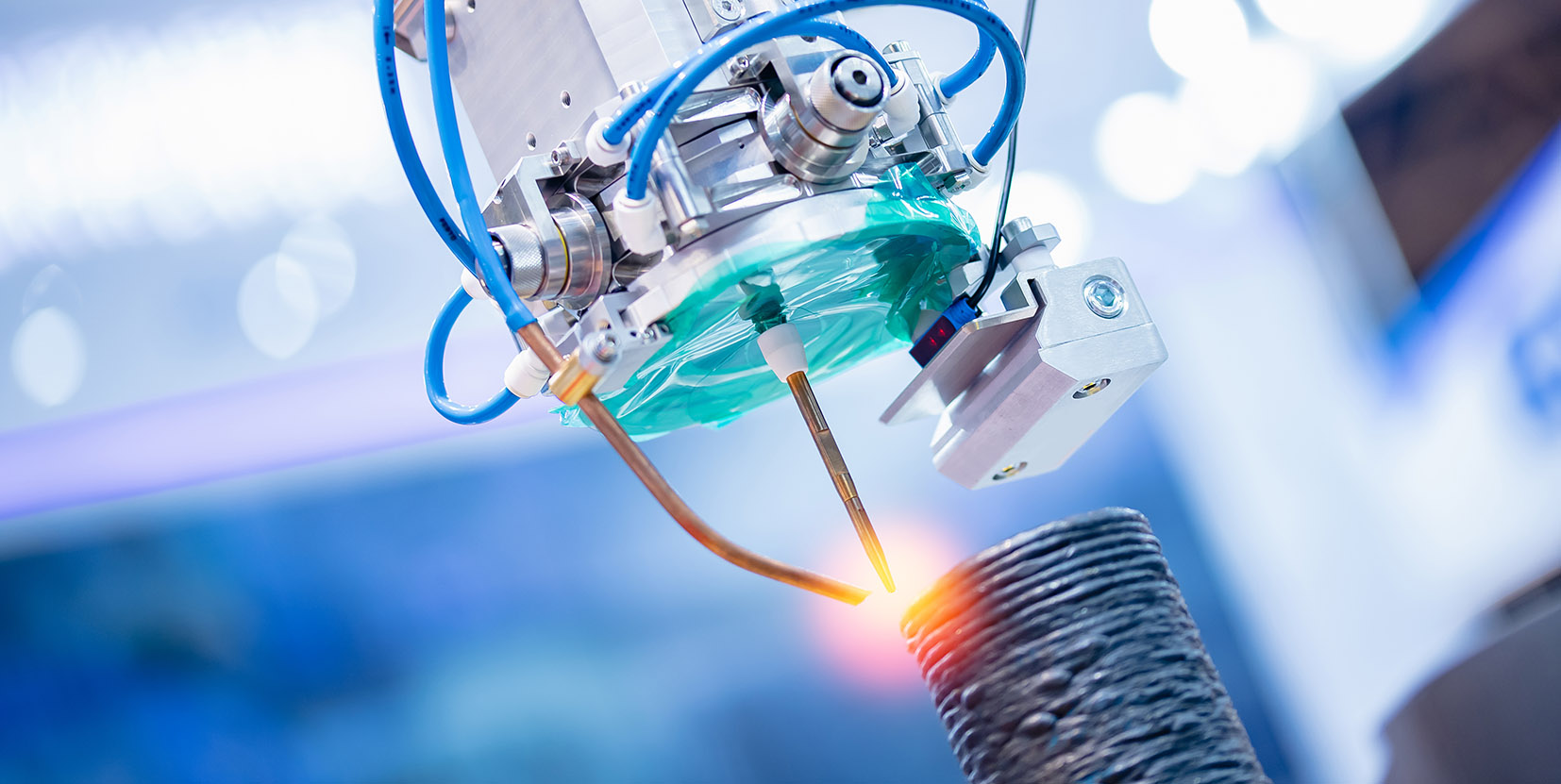

Goodfellow Cambridge, a producer of metals and materials, has developed customized alloy powders for metal Additive Manufacturing. The newly developed powders might raise interest from AM companies or users who are looking to build jet engine structures, store hydrogen, or make medical implants.

With greater alloy composition, particle size and increased flexibility in batch quantity, the new materials would include High-Entropy Alloys (HEA) that have superior properties, critical for future material innovations. The materials are said to deliver great strength and hardness, excellent corrosion/fatigue/fracture and irradiation resistance and good thermal stability, as well as good ductility and magnetic properties.

“We can now create a HEA by using nearly any combination of elements, offering massive potential for advancements in manufacturing design and, interestingly, the production of 3D-printed components,” explained Aphrodite Tomou, head of technical.

The company uses patented ultrasonic technology to produce state-of-the-art alloy powders characterised by their high sphericity (≤ 0.98) and narrow particle size distribution. The company’s technical team can advise on the different compositions required for certain applications and, to help accelerate innovation and more R&D activity, it can supply the powders in batches as small as 100g.

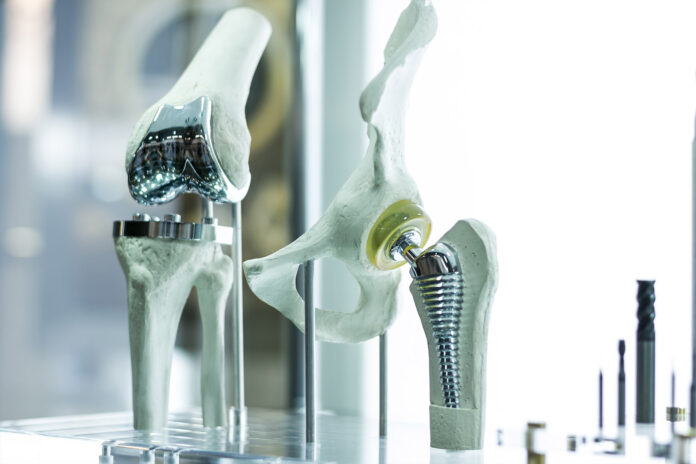

Tomou explains that “high-end technological systems increasingly demand lightweight and intricate components, which can be produced more efficiently and with less material waste using 3D printing.” “[AM] is already taking the weight out of parts destined for airplanes and rockets, whilst, in the medical industry, it will increasingly be used in customised implants and prosthetics.”

She concluded: “It is also a rapidly evolving field and there are many exciting developments on the horizon. For example, researchers are working on new materials that can be 3D printed, such as graphene, nanodiamonds and carbon fibre composites that open up unique properties and new possibilities.”

Goodfellow Cambridge is targeting more than £500,000 of additional sales from this introduction.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com