A new partnership between materials producer 6K Additive and 3D printer manufacturer Freemelt will enable the platform of the latter to experience the refractory metal powders of the former.

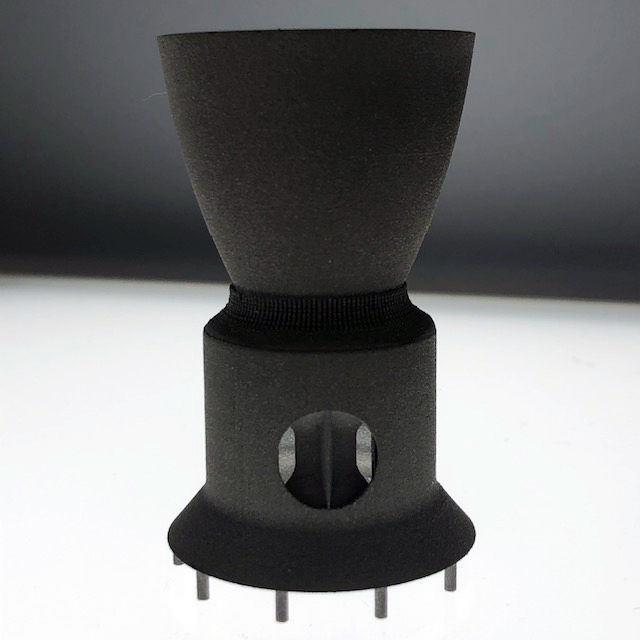

The announcement follows the recent announcement of the development of refractory metal powders by 6K Additive. As a reminder, Freemelt develops an open-source 3D printing platform based on Electron Beam Powder Bed Fusion (E-PBF).

The refractory materials will enable applications for hypersonics, for instance, where extreme temperatures, speed, shifting directions and altitude dynamics often play a key role in their success.

Dr. Ulric Ljungblad, CEO of Freemelt added, “The market is consistently asking us for performance materials and partnering with 6K Additive gives us and our customers a material supplier that not only delivers high-quality metal powder but is quickly commercializing the sought-after performance materials like tungsten and other refractory metals. The new partnership helps us and them push the limits of what’s possible with 3D printing.”

Both companies continue to advance in their respective field of activity: 6K with the recent completionof a 45,000 sq/ft powder production facility in Burgettstown, PA and Freemelt with the launch of a German market subsidiary and signature of new customers such as the KTH Royal Institute of Technology in Sweden and the Polytechnic University of Turin in Italy.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com