QUALUP SAS, an industrial 3D printer manufacturer headquartered in France, will unveil two solutions that will enhance 3D printing of high-performance materials: PIVOT and QU PREDICT. The PIVOT rotating printhead features an unusual rectangular nozzle shape which facilitates the extrusion of a characteristic ribbon of material instead of a round filament thread.

Since this printhead dynamically adjusts the orientation of the nozzle, much faster print speeds are possible at a high accuracy level. This provides better control over the trajectory, which is particularly advantageous when printing complex patterns and achieving smooth surfaces. Made from lightweight metal, PIVOT is adaptable to various materials for printing at high temperatures and up to 300°C.

Meanwhile, QU PREDICT addresses the issues of deformation and warping when using high-temperature polymers. QU PREDICT relies on predictive AI to analyze G-Code proactively before the 3D printing process starts.

It then develops a visual report that signals risk areas and prints are done with optimal success without creating a series of trial-and-error adjustments during the print process.

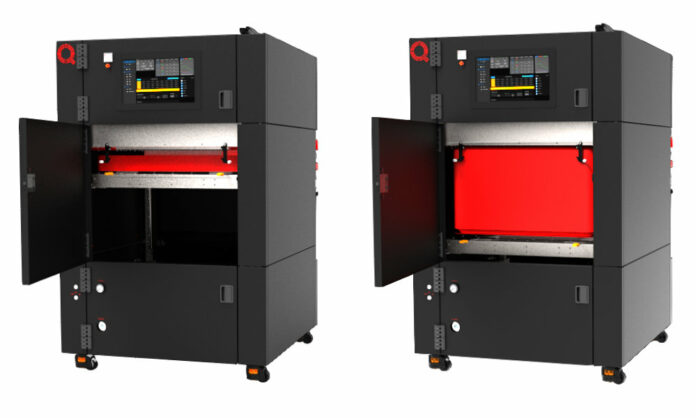

Both innovations are compatible with QUALUP‘s proprietary Qu4 HT 3D printer and are available as standalone solutions for linking other 3D printer systems. For those interested, QUALUP is opening a beta tester program at Formnext 2024, Hall 12.1, Booth A127, where attendees can explore these latest technologies.

Author: Nagarjun M

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.