Every megawatt of renewable energy and every drop of cleaner fuel depends on the equipment that makes it possible. Yet, the manufacturing process of this equipment carries a heavy carbon footprint. For energy equipment manufacturers and energy companies in general, the question is no longer whether to act to reduce carbon footprint, but which applications can truly move the needle.

Although decarbonization is a concern for all industries, energy companies and energy equipment manufacturers (EEMs), in particular, are often the easiest targets.

They are at the intersection of heavy industry and the energy transition. Their expertise in the development and supply of turbines, compressors, pumps, generators, valves, and other industrial hardware that underpin oil & gas, power generation, and renewables makes them critical to both fossil and renewable energy sectors.

This implies that meeting regulatory requirements for decarbonisation calls for a fundamental shift in how industrial hardware is designed and produced within factories.

If the process involves questioning established practices, it also highlights the need to demonstrate why EEMS must tap into certain applications. Addressing this grey area is the goal of this article.

First, what are the decarbonization challenges faced by EEMs?

With stricter regulatory pressure, especially that related to ESG legislation, energy OEMs must reduce both their operational and embedded carbon emissions across the supply chain.

That said, the way their products are made has a domino effect on several aspects of their business, including carbon footprint. Additive manufacturing technology provider 3D Systems refers to them as energy engineering innovation challenges.

- Manufacturing and operations

Existing manufacturing equipment in the field often leads to high energy consumption in production. This equipment may include casting, forging, machining, and welding processes.

According to Pierre Van Cauwenbergh, Ph.D., Senior Application Engineer, Application Innovation Group at 3D Systems, “the key for energy efficiency resides in the development of optimized components to get more out of the equipment from the least amount of input energy, all within rapidly narrowing environmental standards.”

- Part obsolescence and reliability

Conventional manufacturing processes as the ones mentioned above, limit design optimization, making it harder to reduce weight and improve energy efficiency in industrial hardware. Therefore, extending the lifespan of components is harder when parts are not designed for easy repair, refurbishment, or recycling.

“Whether you need to urgently replace a part to get your turbomachinery equipment back up and running or you are developing carbon capture technology for urgent deployment, you need fast turnaround design to manufacturing solutions,” Van Cauwenbergh explains.

Additionally, “with the obsolescence of older equipment and high efficiency targets of newer systems, continuous operation with minimal maintenance is essential.”

- Supply chain and economic viability

To mitigate supply chain risks, accelerate time-to-market, and reduce component manufacturing costs, producing locally, on-demand, and reducing the number of components to decrease the assembly cost must be part of the equation.

These challenges highlight the fact that EEMs rely on traditional processes that are less efficient, more wasteful, and harder to decarbonize. They also bring additive manufacturing (AM) into the picture, probably not as the only answer, but certainly as a tool that can directly address some of these pain points.

What specific applications and technologies can help EEMs reduce their carbon footprint today?

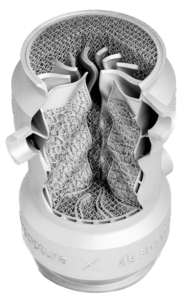

Energy equipment is usually large, highly complex, and subject to strict safety/certification standards. AM has made progress in this space, and is already applied in the manufacturing of turbines, compressors and pumps, as well as valves.

Taking the example of a turbo pump housing, 3D Systems has demonstrated how additive manufacturing (AM) can save both time and costs for a customer, while also reducing their carbon footprint.

After a strategic consulting phase to identify the customer’s needs, the engineering team took just ten days to design and validate a new part. The design was developed in collaboration with the customer using Design for Additive Manufacturing (DfAM) techniques.

To prepare, optimize, simulate, and 3D print the new part, the team relied on 3DXpert software. Using its NoSupports™ build strategies, they were able to deliver a part in just 4 hours with 69% fewer supports.

Production was carried out on 3D Systems’ Direct Metal Printing (DMP) solution, requiring 75 hours to complete the build. The part, with a diameter of 445 mm, was printed in LaserForm Ni718 alloy. Thanks to DMP, the build achieved a 14% faster print time with fewer supports compared to conventional approaches.

The post-processing stage, which included wire EDM and glass bead blasting, took 6 hours. Once the turbo pump housing was completed and approved, the team moved forward with scaling up production and transferring the technology to the client.

“Incorporating 3D printing solutions into component manufacturing workflows from energy production and oil and gas sector infrastructures to decarbonization technology, enables you to rapidly deliver part designs that maximize the performance, quality, and yield,” Van Cauwenbergh points out.

“Incorporating 3D printing solutions into component manufacturing workflows from energy production and oil and gas sector infrastructures to decarbonization technology, enables you to rapidly deliver part designs that maximize the performance, quality, and yield,” Van Cauwenbergh points out.

This example is one among many that gives an idea of how much time and costs can be saved while relying on AM to address part obsolescence with modern manufacturing equipment, locally.

With over three decades of expertise in the field, and collaboration with energy companies, 3D Systems has helped them address several engineering challenges that were keeping them awake at night.

This results in improving thermal management with heat exchangers, increasing fuel efficiency and performance with consolidated components and optimized geometries, delivering complex metal casings and ducting, without tooling time and costs or even producing more efficient opened and closed impellers, faster and at lower cost.

Technology gaps that require attention and how 3D Systems can already help address existing challenges

To address supply chain risks, producing locally and on demand is key. For energy OEMs, the easiest path forward is often to invest in advanced additive manufacturing (AM) solutions. That said, I know buying a 3D printer is not like picking up your favorite pastry; it requires time, strategy, and a commitment to navigating the learning curve.

For companies new to AM, and even for those looking to better manage expectations, I can’t stress enough the importance of working closely with Application Innovation Group (AIG) experts. In my view, their guidance is invaluable to accelerate the development of advanced applications and ensure the successful adoption of additive manufacturing solutions.

“Through training, consultation, and the transfer of prequalified manufacturing processes to your site, our dedicated team works with you across every step, from part design to post-processing,” Van Cauwenbergh concludes.

This content has been created in collaboration with 3D Systems