To help researchers distinguish what’s part of an implant and what cells or tissue can make the structures easier to track and monitor inside the patient’s body. For that, University of Oregon bioengineers and chemists have created fluorescent 3D-printed structures.

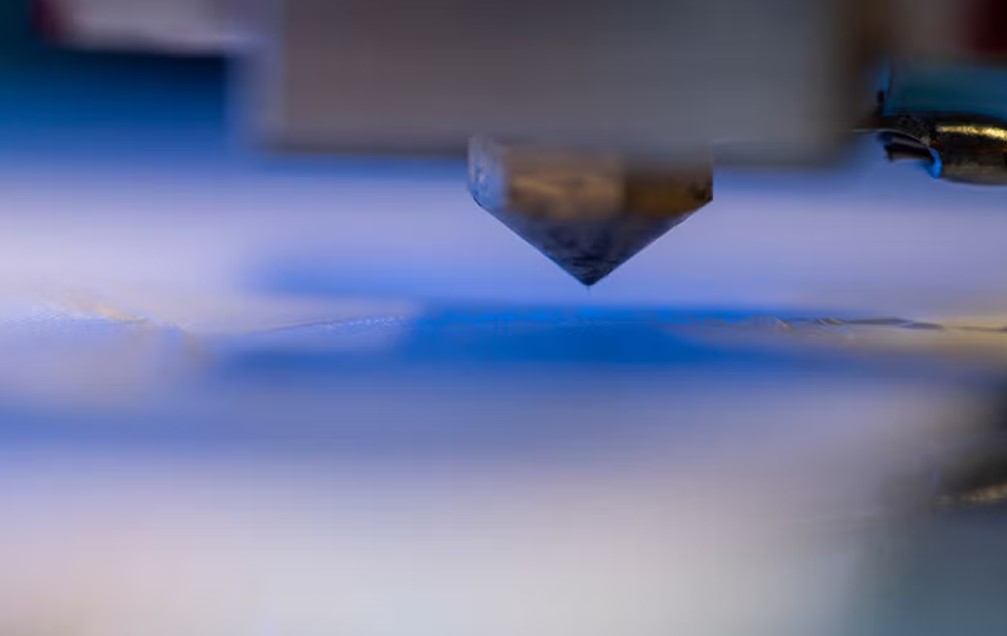

The team has therefore developed a technique called melt electrowriting, which allows relatively large objects to be 3D printed at fine resolution. This process allows for the production of mesh scaffolds that could be used for various types of biomedical implants – implants that could serve applications such as wound-healing technology, artificial blood vessels, or structures, helping to regenerate nerves.

This work is a collaboration between Paul Dalton’s engineering team and Ramesh Jasti’s chemistry lab.

People had tried to make the scaffolds glow in the past with little success, Dalton said. Most fluorescent molecules break down under the lengthy exposure to heat required for his 3D printing technique. The Jasti lab’s nanohoops are much more stable under high temperatures, a press communication explains.

Though both groups might make their craft look easy, “Making nanohoops is hard, and melt electrowetting is hard to do. Hence, the fact that we were able to merge these 2 complex and different fields into something simple is incredible,” said Harrison Reid, a graduate student in Jasti’s lab.

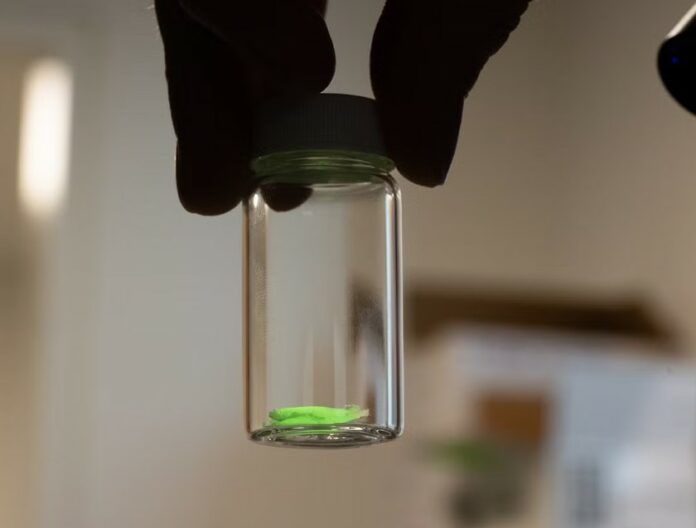

The researchers discovered that adding a small amount of fluorescent nanohoops to the 3D printing material results in structures that glow for extended periods. Since the fluorescence is triggered by UV light, the scaffolds remain transparent under regular lighting conditions.

A battery of tests was conducted to confirm that adding the nanohoops didn’t affect the strength or stability of the 3D-printed material. They also confirmed that adding the fluorescent molecules didn’t make the resulting material toxic to cells vital for biomedical implants & a key baseline that needs to be met before moving closer to the human application. The team now envisions various possible applications for the glowing materials they have created.

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.