As part of a joint study, the Institute for Production Engineering and Photonic Technologies (IFT) at TU Wien and research company FOTEC, studied the effects of varying process parameters on the geometric and thermomechanical properties of additively manufactured parts.

The study was conducted as part of the interdisciplinary cooperation project Ad-Proc-Add, with Dipl.-Ing. Dimitrii Nikolaev and Dipl.-Ing. Ismail Yavuz. The team led by Univ.-Prof. Dr. Friedrich Bleicher from the Institute for Production Engineering and Photonic Technologies (IFT) at TU Wien, investigated the energy efficiency of post-processing methods and evaluated the possibility of vibration-assisted drilling and machine hammer peening (MHP) on components produced using Laser Powder Bed Fusion.

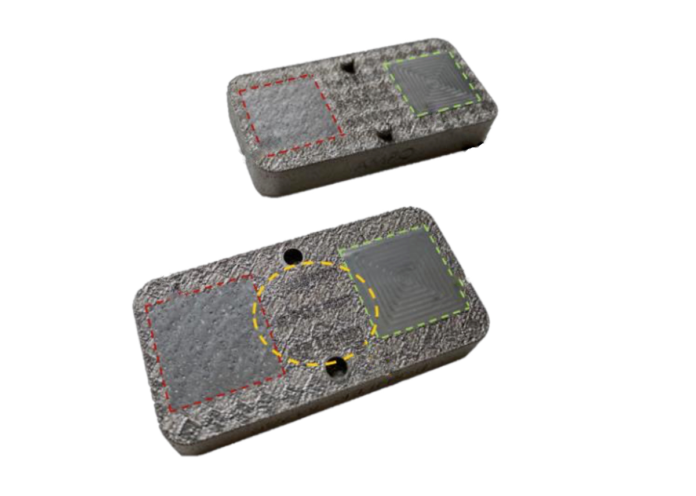

The expert team, in collaboration with the research and technology transfer company FOTEC, confirmed through the study that vibration-assisted drilling can be successfully applied to additively manufactured components to reduce cutting force by 30% compared to conventional drilling when working with martensitic steel alloys. Additionally, machine hammer peening showed effective surface smoothing and can be considered a recommended treatment for functional surfaces of additively manufactured parts.

The researchers also found that a minimum material thickness of 3.5 mm is required for freestanding surfaces of heat-treated AlSi10Mg components produced using Laser Powder Bed Fusion (LPBF) to avoid plastic deformation. When using a smaller impact head and a parameter set with more distant impacts, a thickness of 3 mm may be sufficient. However, thin-walled components with wall thicknesses below 3 mm should not undergo MHP treatment due to the high risk of plastic deformation.

The results of this study provide important insights for developing more effective and energy-efficient post-processing methods for additively manufactured parts, as well as for optimising process parameters and material properties. These findings can assist system and service providers in developing new products with enhanced functionality and enable end-users to implement additive-subtractive process chains with higher productivity and increased economic and environmental efficiency.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com