3D Systems is expanding its high-speed Figure 4® technology through innovation tailored to bioprinting and regenerative medicine

Experts increasingly see the necessity to explore the powerful combination of 3D bioprinting and regenerative medicine to replicate native tissues of the human body and heal diseases that cannot be always healed conventionally.

Apart from medical technology companies, a short list of additive manufacturing technologies providers are starting to make their first steps into this world. One of them is 3D Systems that recently debuted on regenerative medicine and bioprinting solutions.

A collaboration between 3D Systems, United Therapeutics Corporation and its organ manufacturing and transplantation-focused subsidiary, Lung Biotechnology PBC, led to the development of 3D printing systems for solid-organ scaffolds.

This work is just a starting point that gives the manufacturer a more in-depth perspective on the various ways to invest, further develop, and commercialize solutions for the diverse application opportunities in regenerative medicine, including the development of non-solid organ applications requiring biologically sustainable vasculature.

“Over the last years as bioprinting and regenerative medicine have evolved, we’ve seen a growing need to place cells at high-resolution in a nurturing matrix to produce complex tissues,” said Chuck Hull, co-founder, executive vice president and chief technology officer, 3D Systems. “Precise 3D printing with hydrogels, followed by perfusion of cells into the printed scaffold is the best way to achieve this, and we are thankful our work with United Therapeutics has given us the opportunity to advance and perfect this technology.”

The development of 3D printers for solid-organ scaffolds

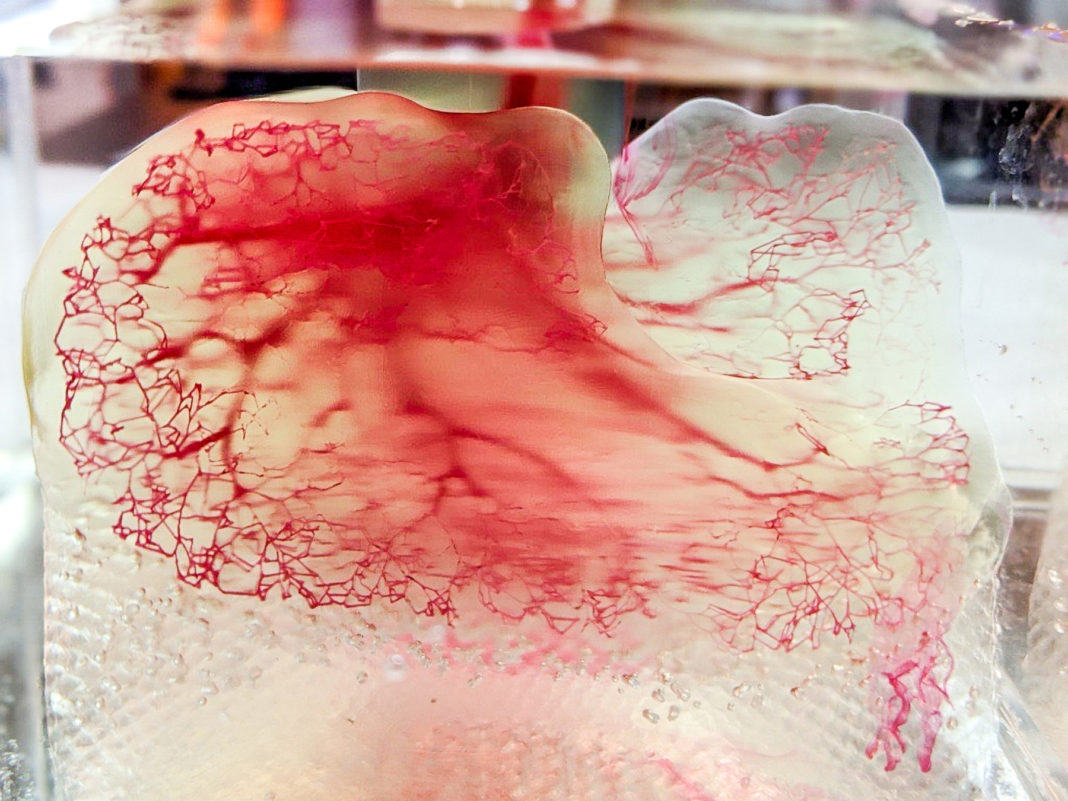

With the goal of developing a 3D printing platform for lung scaffolds that is capable of full size, vascularized, rapid, micron-level printing, 3D Systems combines its expertise in hardware, software, and materials science with the one of United Therapeutics in regenerative medicine.

Their collaboration leads to advancements in lung modeling, 3D printing, as well as material formulation using a unique rhCollagen, and material handling to yield significant capabilities in bioprinters and biomaterials for lung manufacturing.

As a result, 3D Systems has built a portfolio of unique capabilities specifically designed to address the requirements of regenerative medicine applications.

The newly developed Print to Perfusion™ process enables 3D printing of high-resolution scaffolds which can be perfused with living cells to create tissues. The ability to print large, vascularized, highly detailed hydrogel scaffolds at rapid speeds is now opening new opportunities for a range of tissue applications.

To advance these efforts, 3D Systems is expanding its high-speed Figure 4® technology through innovation tailored to bioprinting and regenerative medicine. Building upon these capabilities, the company – in collaboration with its partners – will be able to advance innovation into numerous applications within the human body.

The company also believes these capabilities have the potential to enable novel laboratory testing methods to accelerate the development of new drug therapies while reducing the need for animal testing.

Commenting on the future of regenerative medicine at 3D Systems, Dr. Jeffrey Graves, president and CEO, said, “The progress that Chuck Hull and his team have made over the last three years, in collaboration with the Team from United Therapeutics, has been absolutely remarkable. Through unique developments in new printer hardware, software, and biomaterials technology, they have laid the foundation needed for accelerated commercialization of bioprinting at 3D Systems. Taking a strong application focus we will now expand our commercialization efforts in this nascent industry, which we believe will experience significant growth over the next decade. We expect these efforts to bring substantial benefits to the healthcare patients in critical need, both through direct applications within the human body, as well as in accelerating the development of drug therapies in the pharmaceutical industry. We anticipate regenerative medicine to be an exciting growth driver for our healthcare business over the next decade.”

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com