The Virtual Foundry, a material producer based in the USA, has added the H13 Tool Steel Filament to its portfolio of materials. The material producer is best known for developing filaments for FFF metal 3D printing.

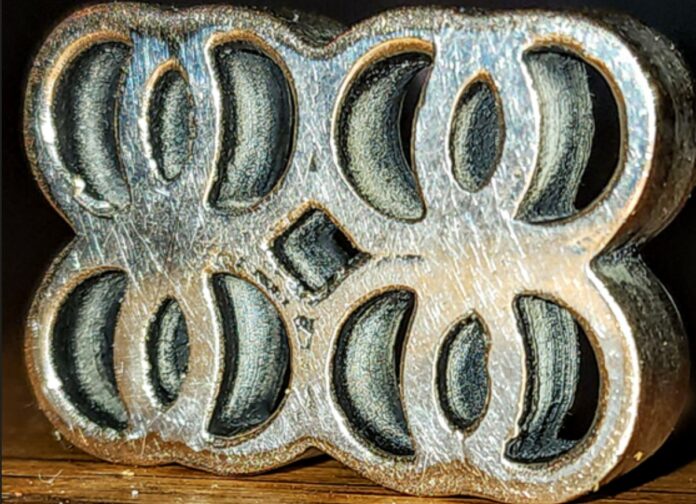

Ideal for wear resistant and high strength parts, the new material is a high-speed steel for Fused Filament Fabrication (FFF) Material Extrusion (MEX). It is said to be compatible with all common FFF Additive Manufacturing machines. Tool Steel H13 Filamet™ prints just like all of the other metal, glass and ceramic filaments from The Virtual Foundry, which also happens to be very similar to printing regular PLA, the company says. After the initial build, 3D printed parts are processed into pure metal using standard sintering furnaces, which are also available via The Virtual Foundry.

“This is the fourteenth sinterable material available in our online store,” stated Bradley Woods, founder/CEO of The Virtual Foundry. “With the introduction of 3D printable Tool Steel, we’re taking this revolution to the next level. Now, anyone can create previously impossible Tool Steel parts using common 3D printers. With the convenience of 3D printing fully in-house and no need to send out for processing, this is a significant advancement on many levels. We couldn’t be more proud to be at the forefront of this innovation.”

Key specifications

- Diameter:75mm only, for this introductory offer

- Weight:25kg only, for this introductory offer

- Filawarmer Needed:No

- Nozzle:Hardened Steel, 0.6mm

- Material Load by Mass:8%

- Filamet™ Density:56 g/cc

- Sintering:Untested *

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.