Zetamix, the additive manufacturing brand of material producer Nanoe, has unveiled a new version of its 316L stainless steel filament. The material is currently undergoing beta testing with the Royal Dutch Navy and MGB, an expert in precision parts machining.

Remember? The Royal Netherlands Navy (RNN), is currently looking to produce 3D printed parts directly on site. In this vein, they are currently working with Nanoe to explore the production and viability of ceramic and metal 3D printed parts.

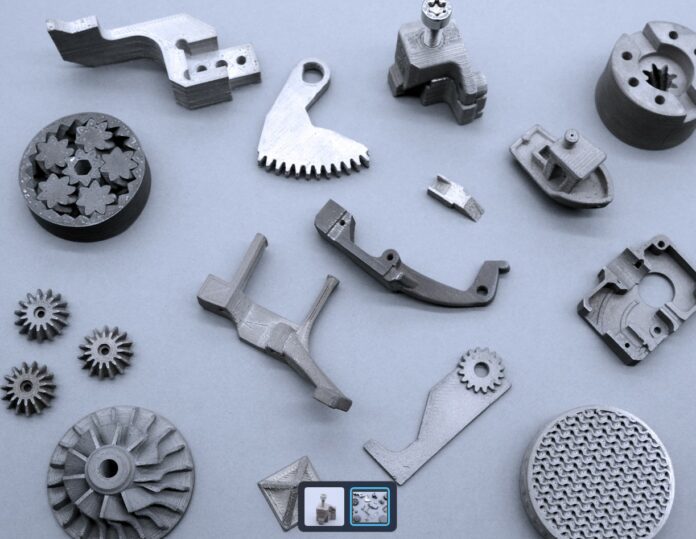

With an improved formulation, the new filament can deliver better dimensional accuracy and enable the production of larger parts with more important overhangs.

“Unlike other solutions that require post-processing by a service provider, our system enables users to easily print stainless steel in-house,” Guillaume de Calan, CEO of the company comments.

Other differences with the previous formulation that required sintering under pure hydrogen – therefore a specific type of furnace – include a simplified post-processing phase. According to Zetamix, to reach a density greater than 90%, the 316L stainless steel filament must be chemically debinded and thermally post-processed. This last step includes a thermal debinding and a sintering under 2.5% hydrogenated argon. Zetamix 316L can therefore be sintered under a wide variety of furnaces, including the Zetasinter furnace of the company.

The improved formulation therefore opens up the utilization of 316L stainless steel to a wider range of laboratories and industries across the world.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com