USA-based advanced manufacturer FATHOM is celebrating a milestone in its activities. The company has received a patent for the systems and methods powering its online digital manufacturing platform.

The patent relates to the company’s internal and external platforms leveraged for the emission of price quotes for 3D objects with checkout option, including selection of units, materials, finish, and quantity of additively manufactured parts to be made. FATHOM is also ISO 9001:2015 certified, ITAR registered, and DFARS compliant.*

Last year, the company joined forces with GoEngineer, to create a digital manufacturing ecosystem so that each other’s customers could benefit from software, hardware, and manufacturing solutions. This ecosystem is just one example that illustrates the ongoing efforts of Fathom to distinguish itself among others of the same range. At the applications level, one can recall the involvement of the company in the crowd-sourced vehicle concept. Every single milestone achieved until here has been marked by several award-winning recognitions received by various institutions in the Bay Area.

“These exciting milestones for FATHOM further highlight our continued commitment to solutions that transform how products are designed, prototyped, and manufactured,” said Michelle Mihevc, Co-Founder and Principal at FATHOM. “Evolving at a fast pace in meaningful ways is how FATHOM maintains its unique position in the marketplace. The core of everything we do is about offering prototyping and production services that help companies drive greater innovation while also accelerating project timelines.”

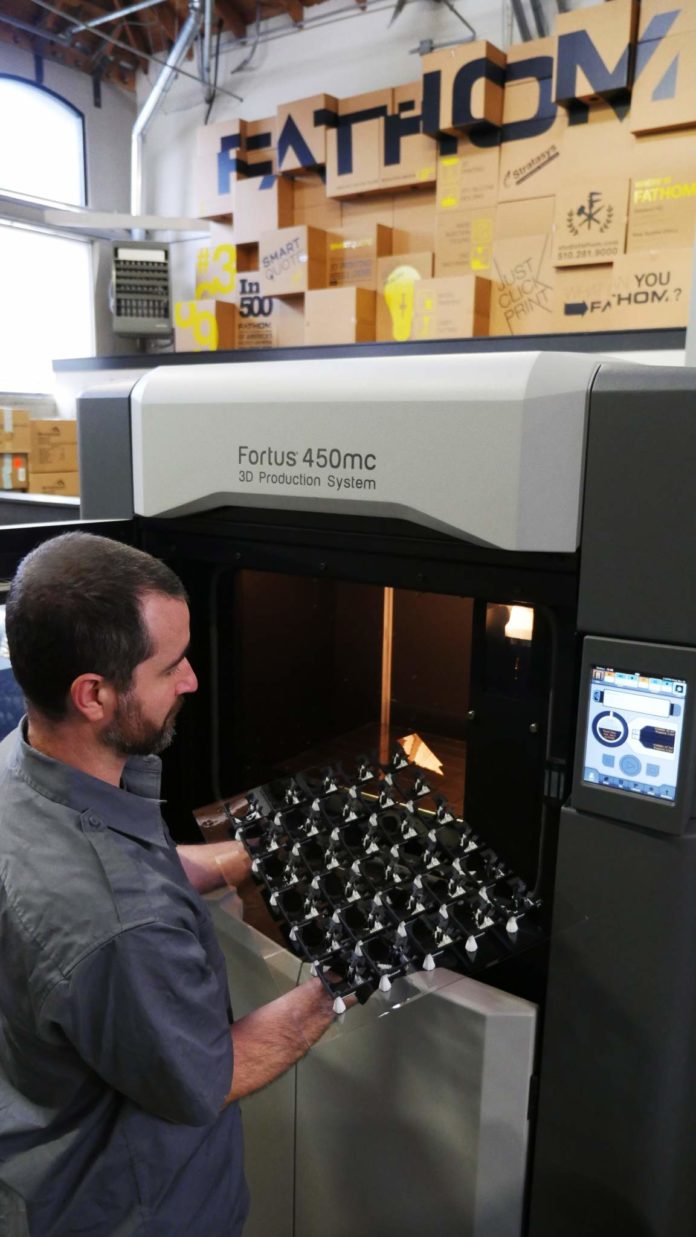

This adventure in the 3D printing industry took a significant leap in 2008 when FATHOM got its award-winning start selling and supporting enterprise-level 3D printing and additive manufacturing systems.

Co-founders Stump and Mihevc then opened a full-service additive manufacturing facility in 2012. FATHOM’s Seattle-based production center opened the following year. Today, FATHOM’s team of experts specialize in additive and traditional manufacturing services (CNC machining, urethane casting, tooling, and injection molding), plus hybrid processes (blending additive with subtractive and formative methods to achieve results not previously possible).

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram !Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com