Following a $1.6 million contract signed with the U.S. Department of Defense, the ExOne Company will develop a portable 3D printing factory.

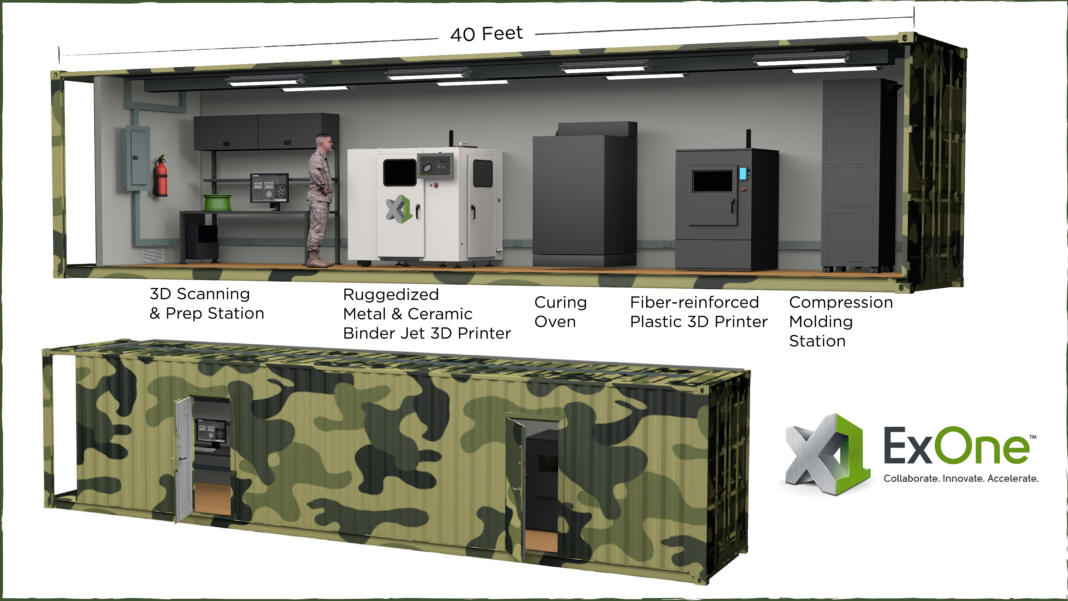

The 3D printing factory pod would be set up in a standard shipping container, up to 40 feet long (28,27 m2), to be deployed directly in the field, via land, sea or air, to manufacture parts, support war theaters, disaster relief, or other remote operations.

The idea of the portable 3D printing factory is very similar to the Mobile Smart Factory, a concept developed by Bionic Production that includes all the manufacturing stages of the production into one container. Except that this time, in the container, operators in the field will only work with ExOne’s dedicated products.

In this case as well, the manufacturer of industrial sand and metal 3D printers will need to simplify the use of hardware and software with software and training, so the pod can be used with minimal technical knowledge. Furthermore, a digital library will be provided to the operators on-site so that they will only choose a 3D file to print and send it to the 3D printer.

“Binder jet 3D printing is a critical manufacturing technology for military use because of its speed, flexibility of materials, and ease of use,” said John Hartner, ExOne’s CEO. “We’re excited to collaborate with the U.S. Department of Defense and other partners to make our 3D printers more rugged for the military, which will also benefit our other manufacturing customers. Most importantly, we know that years from now, our technology will play an important role in filling critical needs quickly.”

A special military-edition 3D printer in progress

To meet the request of the DoD, the manufacturer will have to develop a unique 3D printer that will best fit in such environment. Based on its binder jetting technology, the 3D printer should be able to process over 20 metal, ceramic and other powder materials into direct final products or tooling. In a nutshell, the total number of materials that have already been qualified for its other 3D printers.

However, as far as the portable 3D printing factory is concerned, its development will be carried out in collaboration with Dynovas, Inc, in materials engineering, composites manufacturing, and DoD weapons systems and Applied Composites – a provider of complex composite components, assemblies, engineering, and tooling.

As far as the benefits are concerned, there are inevitably the ability to save time and costs for those workers in remote areas.

In a press communication, ExOne explains that by enabling a military team on-site to 3D print parts as needed, the downtime in a crisis can be reduced from weeks or months to only a few days or less, while also reducing military costs. Ideally, military personnel would 3D print a digital file of a broken or damaged part and have a finished product in less than 48 hours without conventional tooling in the self-contained pod. This approach would save critical time (machined tooling to create parts typically takes 4-6 weeks), while also reducing waste and the need to carry expensive inventory in crisis zones.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com