ExOne has added the widely used stainless steels 316L and 17-4PH to the list of materials offered through instant quoting.

As a reminder, the company’s binder jetting technology can already process 21 materials and other materials will certainly follow at the end of the five projects that are currently in progress across various US-based universities.

However, as far as the new stainless steels are concerned, they could be processed on the company’s Innovent+ and X1 25Pro metal 3D printing systems. Both machines integrate a Triple ACT system, an advanced compaction technology which ensures density and repeatability in metal binder jetting. The company’s 3D Printers which integrate this technology are acknowledged for their ability to deliver sintered dimensional accuracy of +/- 2.5% on a first print run, with better results possible after additional sintering optimization.

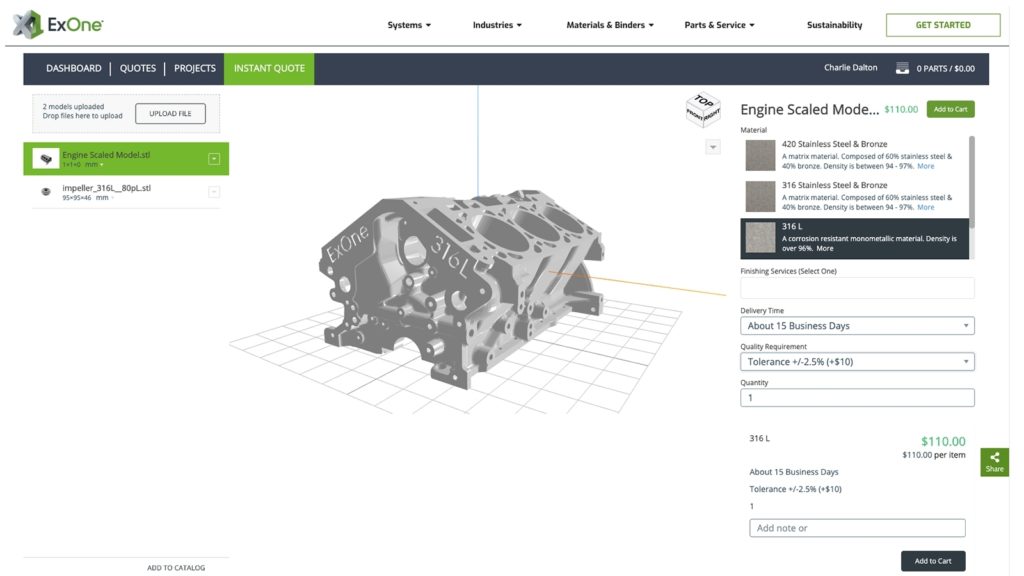

To order the new materials, a new Quick Ship online dashboard is now available online. Customers could upload a qualifying digital design file for an instant quote, purchase, as well as create an account to track projects. More than 30 file types are accepted including STL and STP files.

“After two years of supplying thousands of 316L and 17-4 parts to select industrial customers, our updated Quick Ship services will now allow any customer to easily acquire and evaluate affordable single-alloy parts 3D printed with binder jetting,” said John Hartner, ExOne CEO.

“The launch of Quick Ship services for single-alloy metals represents a key step forward in our development of metal binder jetting, and one that signifies our continued confidence in this technology,” said Rick Lucas, ExOne Chief Technology Officer and VP of New Markets. “We also have plans to expand the number of material offerings and size of printable parts in our Quick Ship services by year-end.”

Lastly, it should be noted that the launch of these new materials will not interrupt the distribution of the well-known 316 and 420 materials infiltrated with bronze and compatible on the classic M-Flex and R2 metal 3D printing systems. Indeed, those infiltrated parts deliver a variety of functionality and finish benefits, and can be produced within 10 business days.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com