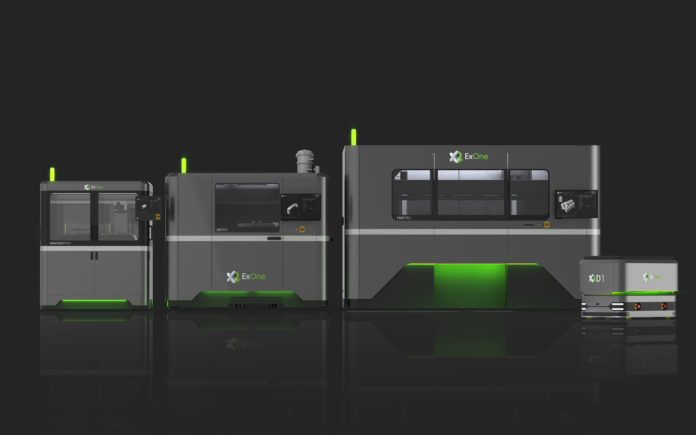

ExOne has unveiled the InnoventPro, described as the most advanced entry-level binder jetting system for printing metals, ceramics and composites. The InnoventPro is an upgrade of the Innovent+, one of the best-selling metal binder jetting system in the company’s portfolio.

In terms of software compatibility, the manufacturer will Siemens Digital Industries as a partner for the production version of the machine that should be unveiled in the second half of next year. Siemens has a wide range of trademarks and is currently developing an end-to-end AM software solution. For now, as part of this collaboration, customers who order an Innovent+, could benefit from an incentive program for the InnoventPro+ prior to the system’s commercial availability.

Designed for academics, researchers, and a full spectrum of manufacturers, from machine and MIM shops to high-volume producers, the new 3D printer would be a good candidate for any users that would like to produce metal parts quickly, affordably and sustainably.

“Customers around the world already love the Innovent+, and based on their feedback, we’re going to give them an updated entry-level system that’s bigger, faster and smarter than ever,” said John Hartner, ExOne.

Built with an improved range of technical specifications, the InnoventPro offers two new build sizes, a 3-liter and a 5-liter, with print speeds topping 700 cc/hour. Interestingly, it will be equipped with the same recirculating printhead modules used on the X1 25Pro® and X1 160Pro™ metal 3D printers, allowing users to easily scale up from R&D to high-volume production. These recirculating printhead modules are a good option for users that would like to take advantage of particulate binders.

How this advances the field of binder jet 3D printing

First patented in 2018, with related patents pending worldwide, ExOne explained in a press communication its “inkjet-printable nanoparticle suspensions” are slated for commercial deployment in the InnoventPro. This all-new class of ExOne NanoFuse binders advances the field of binder jet 3D printing in critical ways.

Because nanoparticles fill in the interstices between powder bed particles and can bond at lower temperatures, they enable stronger green parts. In turn, this enables 3D printing of larger parts and finer features, delivering sharper corners and edges. These new binders can also improve the resolution and sinterability of high-demand metals, such as copper and aluminum.

According to Rick Lucas, ExOne CTO and VP, New Markets, the InnoventPro and new NanoFuse binders enable ExOne to continue leading the way in commercial development of binder jetting:

“Just as the current Innovent+ served as the proving ground for our patented Triple ACT system, which now delivers industry-leading quality in metal binder jetting, the InnoventPro will offer groundbreaking new features in a commercial system. Our patented approach to 3D printing particulate inks in a print bed is opening new doors in binder jetting.”

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com