2026 will provide an opportunity to further spotlight the vertical industries and niche technologies driving the adoption of additive manufacturing. As far as vertical industries are concerned, we’ll look beyond the usual frontrunners (Aerospace & Defense, Healthcare & Medical, and others) to shed light on sectors with untapped yet significant potential.

Across a diverse lineup of partner events worldwide, we highlight below the key trends emerging from Ceramitec 2026, the Industrial Valves Summit, and TCT Asia.

A closer look at ceramic 3D printing solutions and trends through Ceramitec 2026

With 87 exhibitors offering ceramic solutions or services, Formnext 2025 signalled strong activity and growing interest in ceramic 3D printing. While we have always believed there is room for everyone in this market, the rapid growth, paired with the fact that the segment is not yet large or consolidated enough, raises concerns about whether all players can truly thrive in the long run.

Ceramitec 2026 will serve as an important opportunity to look beyond the usual leading names —3DCeram, Lithoz, Schunk Group, XJet, and others— to thoroughly assess these concerns, explore the opportunities ahead, and shed light on the companies that are quietly but significantly shaping the ceramic AM landscape.

Hidden enablers: How technical ceramics are shaping our world

When ceramitec opens its doors in Munich from March 24 to 26, 2026, one thing will become particularly clear: Modern high technology and many aspects of daily life, whether at home or at work, would be virtually inconceivable without technical ceramics. They are hidden enablers that we all use in everyday life without being aware of them.

Whether it’s in medical technology, electronics, aerospace, or the energy transition, ceramic materials are used wherever other materials reach their limits. They combine hardness with precision, temperature resistance with chemical stability, and electrical insulation with high or low thermal conductivity, as required. The exhibiting companies at ceramitec will show exactly what that looks like in practice.

Modern high technology and many aspects of daily life—whether at home or at work—would be virtually inconceivable without technical ceramics. © Messe München GmbH

Medical technology: precision in the body

Different standards apply in the human body. Technical ceramics such as zirconium oxide or aluminum oxide are biocompatible, and resistant to wear and corrosion. Thanks to these properties, they are predestined for use as implants, joint prostheses or surgical instruments. A hip joint head made of high-performance ceramics, for example, can withstand millions of movements without showing signs of wear. Ceramic dental implants not only aesthetically match the other teeth but are also metal-free.

That makes them the ideal solution for sensitive patients. Ceramic components are also indispensable for bone substitute materials and the smallest components in endoscopic instruments. ceramitec will show how new production processes and materials can further improve the service life and functionality of these components.

Electronics and electrical engineering: hidden performers

They are barely visible, but indispensable: Ceramic substrates and insulators perform key tasks in smartphones, high-performance computers and converters. Aluminum oxide or aluminum nitride ceramics dissipate heat efficiently while at the same time insulating high electrical currents.

They enable miniaturized designs and protect sensitive semiconductors. Ceramics are also the basis for reliability in power and high-frequency electronics, from 5G antennas to inverters in electric vehicles.

Aerospace: materials for extreme conditions

In aerospace, grams and degrees can make the difference between success or failure. Silicon carbide or zirconium oxide ceramics, for example, can withstand temperatures of over 1,500°C without losing their shape.

They protect engines, nozzles and sensors from heat and erosion. Satellites use ceramic components, for example, based on cordierite, in housings, mirrors and for thermal insulation. Precision and stability must be guaranteed there over many years, even with constant temperature changes.

Industrial applications and electric heating technology: robust in continuous use.

Extreme conditions often prevail in industrial processes: high temperatures, rapid temperature changes, aggressive media and abrasive particles. Technical ceramics withstand these stresses, whether as nozzles, bearings, valve components, sliding surfaces, or as indispensable components of heating elements.

In electrical heating technology, for example, ceramic heating conductors and insulators ensure precise temperature control, whether in 3D printers, furnace systems or the glass industry. Their durability reduces downtimes and maintenance costs, which is crucial for sustainable production.

Renewable energies, battery, and storage systems: progress through material innovation

Ceramics play a key role in the energy transition. In fuel cells, they serve as electrolyte and a separating layer, in batteries as a separator or solid electrolyte. Thanks to their ion transport capability and chemical stability, they enable safe and long-lasting energy storage, which is of central importance for electric mobility and stationary storage solutions.

Ceramic components are also indispensable in hydrogen technology: They filter, seal and conduct where metallic materials would fail. They are also key components in electrolyzers and other hydrogen production processes.

Defense technology: protection with minimum weight

Light, hard, and resistant: These properties make technical ceramics an ideal material for protective applications. Ceramic composite armor combines high hardness and strength with low weight, thus protecting vehicles and people from ballistic threats.

At the same time, ceramic sensors and insulators enable reliable functionality even in extreme environmental conditions.

Automotive: ceramics driving tomorrow’s mobility

Ceramic components can be found in almost every vehicle, for example, in lambda sensors, valve seats, brake systems, catalytic converters in the exhaust tract, or high-voltage components.

With the advent of electric mobility, their importance continues to grow. They insulate electric currents, manage heat, and guarantee safety in the battery and drive. Additively manufactured ceramic components also enable completely new designs for lightweight construction and functional integration.

Lifestyle, consumer goods, and household appliances: when aesthetics meets function

Ceramics are no longer just a technical material, but also a lifestyle material. High-strength, color-stable, and scratch-resistant ceramics are used in luxury watches, smartphone cases, and kitchen knives. In household appliances, ceramic heating and sensor elements provide efficiency and durability, light in the oven, or perfect coffee bean grinding.

Analysis technology: precision in the micrometer range

Ceramic materials are the backbone of precise measurements in laboratories and testing systems. They offer dimensional stability, chemical inertness and excellent electrical properties, making them ideal for sensor housings, carrier plates or microfluidic systems. And even the crucible or furnace used daily in the laboratory are also based on technical ceramics. Whether it’s in environmental analysis, medical research or process monitoring, ceramic components ensure reproducible and reliable results.

Ceramics as an enabler of modern technologies

ceramitec 2026 will show that technical ceramics are much more than just a material. Due to their diverse, customized properties, they are a key element in modern technologies and sustainable solutions. From powder technology and additive manufacturing to finished components, the entire range of industrial applications for technical ceramics will be on show in Munich.

How additive manufacturing is advancing valve and component design at Industrial Valve Summit (IVS) 2026

Since its 2022 edition, the Industrial Valve Summit (IVS), a key international event dedicated to industrial valve technologies and flow control solutions, has increasingly positioned additive manufacturing as a strategic theme. AM is explored for its ability to enable complex valve geometries, novel designs, advanced materials (including those for hydrogen applications), digital inventory strategies, certification pathways, and future scenarios for component production.

Additive manufacturing (AM) is already reshaping valve and fluid-component design, but mostly in high-value niches rather than across the board. The trajectory points toward more integrated, topology-optimized, and application-specific components, especially where flow performance, weight, and lead time matter most.

Hopefully, the 2026 edition of IVS will shed light on these trajectory points.

Held every two years, the event attracts around 15,000 visitors and 325 exhibitors (2024 figures). The 2026 edition, scheduled for March 19–21 in Bergamo, Italy, will be structured around six key themes: standardization, digital technologies applied to valves, actuation and control, valve design and materials for severe services, advanced sealing solutions for industrial valves, AI applied to mechanical design, procurement and manufacturing, and additive manufacturing.

TCT Asia 2026

As highlighted in our end-of-year review, China is experiencing significant growth in AM adoption—following a trajectory that differs markedly from Europe and the US. Our presence at TCT Asia 2026, one of the region’s leading events, will provide valuable insights into the specific market drivers, applications, and strategies shaping this unique ecosystem.

Set to take place on March 17–19, 2026, at the National Exhibition and Convention Center (Shanghai), Halls 7.1 & 8.1, the event will showcase the full industry chain from equipment and materials to software and applications.

With 550+ exhibitors, including leading companies from China and the Asia-Pacific region such as BLT, Farsoon, Bamba Lab, and Snapmaker, 100+ forums, and 40,000+ visitors from key sectors, it serves as a major hub connecting the global 3D printing ecosystem across Asia.

Two halls bring together metal additive manufacturing, polymer 3D printing, materials, software, and post-processing—all in one place. Make sure you are part of these vibrant, dynamic, and growing Chinese markets. Make sure you are part of these vibrant, dynamic, and growing Chinese markets.

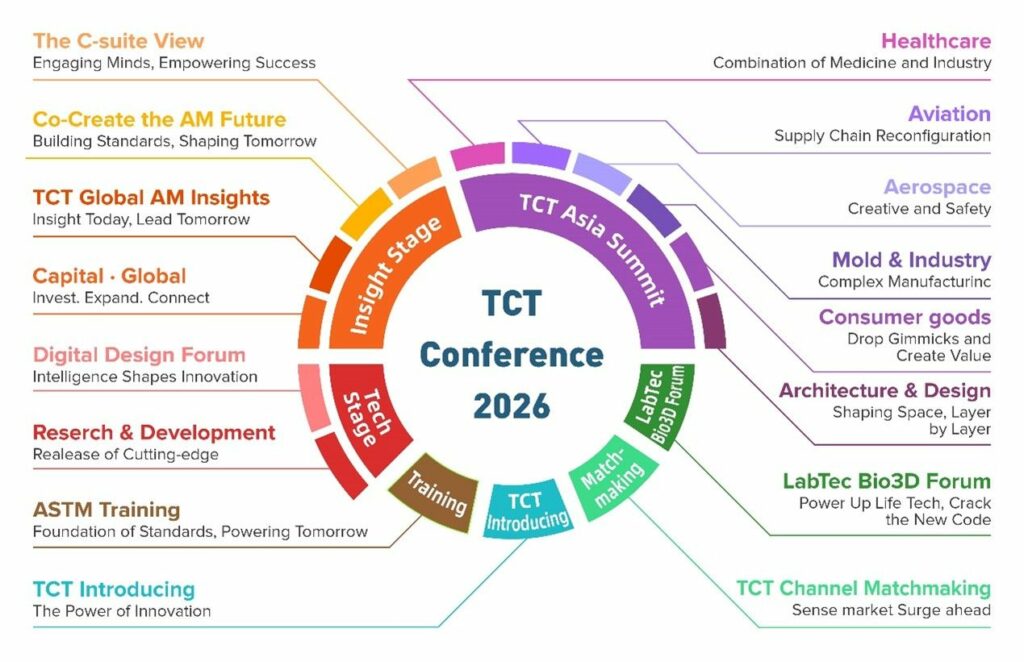

TCT Asia Summit & Forums: Insights from users, experts, and leaders

As the flagship platform of TCT Asia, the TCT Asia Summit unites leading companies, research institutions, design teams, and end-users from the global additive manufacturing community.

As the flagship platform of TCT Asia, the TCT Asia Summit unites leading companies, research institutions, design teams, and end-users from the global additive manufacturing community.

Focusing on key sectors such as aerospace, healthcare, molding, consumer goods, and architecture, the summit highlights real-world applications, showing how additive manufacturing drives structural innovation, process transformation, and industry-wide upgrades.

Complementing the summit, the Tech Stage brings together experts from universities, research institutes, and government agencies to present the latest scientific research, analyze industry trends, and foster collaboration across industry, academia, and research, helping innovations move swiftly from the lab to production.

Meanwhile, The C-Suite View gathers influential entrepreneurs, investors, and commentators to provide strategic insights, market outlooks, and forward-looking perspectives, offering executives and innovators the knowledge to navigate the future of additive manufacturing.

Secure your Fast Track Pack with free registration available before March. Visit https://en.tctasia.cn/ to complete the registration form accurately and get the most from TCT Asia. You’ll receive a confirmation email with your exclusive login.

*This article was first published in the November/December edition of 3D ADEPT Mag. Read our 2025 year in review series here. Featured image: Formnext – Mesago Messe Frankfurt GmbH / Mathias Kutt