Under the leadership of Prof. Florian Thieringer, head of the Medical Additive Manufacturing Research Group (Swiss MAM) at the University Hospital Basel’s Department of Biomedical Engineering (UNIBAS DBE), and the Department of Oral and Maxillofacial Surgery (OMFS), in collaboration with Prof. Raphael Guzman and the Department of Neurosurgery, 3D printed cranial implants produced by 3D Systems‘ point-of-care technologies were used to assist cranioplasty surgeries

The patient-specific 3D printed cranial implants helped support cranial surgeries at the University Hospital Basel in Switzerland and at the Salzburg University Hospital in Austria.

The cranial implants market size is estimated to cross $2 billion by 2030, up from $1.2 billion in 2021 and 3D Systems’ point-of-care solution is likely to speed up that. 3D-printed cranial implants can address issues like trauma, defects and reconstruction in the brain as already seen in previous applications in patients.

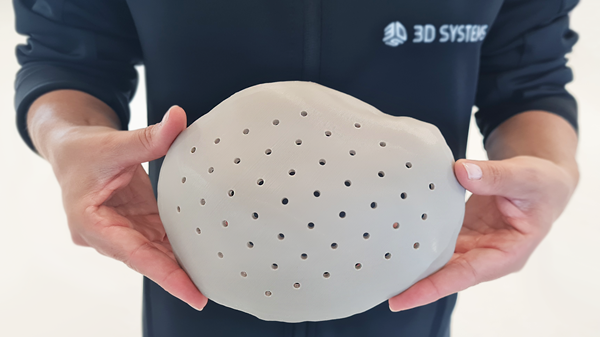

The extrusion 3D printing technology of the company has a unique architecture and design which makes it easy to produce durable biocompatible 3D printed implants using Polyetheretherketone (PEEK) material.

The patient-specific geometries of the PEEK implants help both surgeons and patients. The 3D-printed implants created at the University Hospital Basel were used to replace the disintegrating skull of a 46-year-old man, suffering from stroke-related complications since 2019.

Dr Neha Sharma from the University Hospital of Basel team used CT scans of the patient’s skull and imported them to software to create the 3D printed cranial implants which are unique to him.

The hospital’s 3D printing lab then made the 3D-printed implant with Evonik’s VESTAKEEP® i4 3DF PEEK material on 3D Systems’ EXT 220 MED extrusion platform. The same material has been used in the past for other surgeries in the USA.

The PEEK implants used in the cranial surgery were lightweight, resistant to thermal and ionizing radiation, and were similar to human bone structure. These mechanical properties of PEEK material make it ideal for generating 3D-printed implants.

The 3D printing solutions supplied by 3D Systems ensured effective healthcare applications of the 3D printed cranial implants within sterile environments of the hospital.

Speaking about the matter, the Head of the Additive Manufacturing Research group at the University Hospital Basel, Professor Florian Thieringer said: “The successful implantation at the University Hospital of Basel is a pivotal moment for medical 3D printing, demonstrating its potential to revolutionize patient care. Our collaboration with hospitals across Europe, along with the invaluable expertise provided by POC APP AG around QMS and regulatory guidelines, showcases the power of advanced technology and collaboration in improving healthcare outcomes”.

The Oromaxillofacial Surgery Department at the Salzburg University Hospital also used the point-of-care solution supplied by 3D Systems to create patient-specific 3D printed cranial implants for a 55-year-old man. The patient Rainer Trummer had a deformed skull caused by ossified cranial bones in early childhood.

The clinicians at the hospital used Oqton’s D2P® software to create 3D models from the patient’s CT images and Oqton’s Geomagic Freeform® to complete the design of the patient-specific occipital prosthesis. Based on the design, the 3D printed cranial implant was created using Evonik’s VESTAKEEP® i4 3DF PEEK material on 3D Systems’ EXT 220 MED extrusion platform.

The 3D-printed cranial implants generated in this way, have been used by the neurosurgery department of the Salzburg University Hospital in decompressive craniectomy procedures for aggressive brain swelling.

The Chairman of the Neurosurgery Department at Salzburg University Hospital Prof. Christoph Griessenauer revealed 40 decompressive craniectomies are done in Salzburg every year and the patient-specific 3D printed cranial implants will help in the process. Once the brain swelling reduces the bone is replaced with a patient-specific cranioplasty implant. So far, the hospital has used these 3D-printed implants in four cranial surgeries last month.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com