The independent energy expert and assurance provider DNV has published a new edition of DNV-ST-B203 Additive manufacturing of metallic parts.

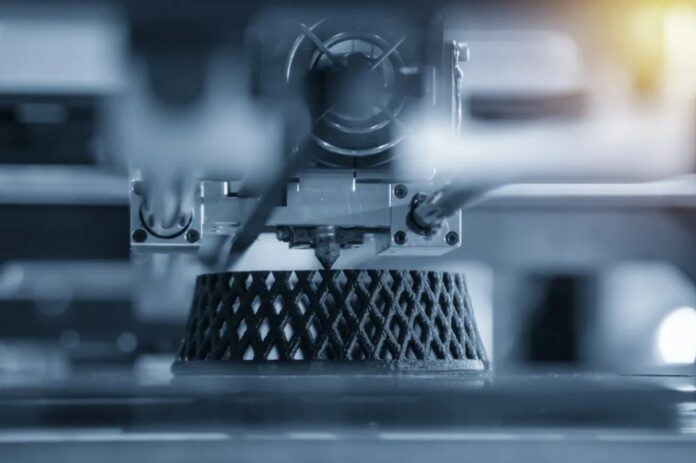

The standard, which is the result of a joint industry project, now includes baseline requirements for the most established Additive Manufacturing (AM) technologies for metal parts and welcomes new concepts for quality assurance for the coming era of data-driven manufacturing.

Additive manufacturing (AM) offers not only another manufacturing technique, with new and unique design boundaries, but also a potential solution to supply chain challenges, reducing lead time and cost by enabling local manufacturing in a global market. AM is an enabler for storing spare parts digitally on a server and shipping them over the internet – rather than in large warehouses with demanding logistical systems.

“Additive manufacturing offers a way of reducing waste of materials from excessive machining operations. The digital nature of additive manufacturing also enables new ways of ensuring quality control, by monitoring through sensors and logging of production trends – which in turn may lead to increased confidence in a part’s quality. One of the basic assumptions for achieving these objectives are standardized levels of quality.” explained Lucy Craig, Director, Growth, Innovation & Digitalization, Energy Systems at DNV.

The new edition of DNV-ST-B203 includes qualification- and production requirements for three new AM technologies, in addition to the two technologies covered in the first edition. The new edition includes provisions for the most established metal AM technologies:

- Directed energy deposition using electric arc, and laser beam (DED-arc and DED-LB)

- Powder bed fusion using laser beam and electron beam (PBF-LB and PBF-EB)

- Binder Jetting (BJT.)

Additionally, the standard now includes:

- Requirements for the qualification of combined manufacturing methods, such as AM features on substrate shapes

- Defined acceptance criteria for non-destructive testing

- Guidance on the definition of part families, that may extend the validity of qualifications

- Guidance on the choice of criticality classes (AMC), that may help end-users to choose the right level of quality assurance for the given application

- Guidance on unconventional inspection techniques and in-process monitoring, that may help manufacturers to improve efficiency and quality, and unlock the design freedom of additive manufacturing.

The standard was the first internationally accepted framework for producing and using high quality additively manufactured metal parts for the oil & gas, maritime and energy industries. It introduced approaches to manage the quality of additively manufactured metal parts, with each approach adapted based on the criticality of a part’s function.

The new edition was made in a joint industry project (JIP) run by DNV’s Technology Centre Oslo. The JIP is called ProGRAM JIP phase 2 and was developed by running practical case studies in parallel to the development of the standard. ProGRAM JIP phase 2 included companies representing end-users, contractors and equipment manufacturers, part manufacturers, AM machine providers and suppliers of material feedstock.

“The learnings from the case studies helped the project to identify important activities in the qualification and production setting. In addition to assisting the work on the development of the standard, the project was able to create parts that can be put into service. And by comparing the resource consumption from part repair with that of conventional part replacement, the project showed that there could be a significant environmental benefit from enabling repair of worn parts with additive manufacturing. The work also continues in ProGRAM JIP phase 3, started in June 2022 and will run into 2024.” said Stian Gurrik, Project Manager ProGRAM JIP phase 3, Technology Centre Oslo, Energy Systems at DNV.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com