Sweden-based manufacturer of binder jetting technology Digital Metal® has launched a new tool steel alloy for its metal 3D printing technology.

Named DM D2™, the tool steel alloy completes a portfolio that already includes superalloys DM 247 and DM 625; the first one being based on the non-weldable MAR M247 and the second one being an Inconel 625-grade material.

The DM D2™ provides an effective combination of abrasive wear resistance and toughness. It would be a good candidate for cutting and deformation tools and cold work applications that require sharp edges and abrasion resistance.

According to Digital Metal®, when toolmakers specify a steel for their equipment, they often choose D2 as it is hard enough to suit the task of stamping and forming other metals without losing its shape.

The DM D2™ is acknowledged as a versatile high-carbon, high-chromium D2 tool steel alloy that delivers high wear resistance. It can also be heat-treated to high hardness and compressive strength.

“We have been receiving more and more requests for a D2 tool steel suitable for use with our printers. We have designed the DM D2 to deliver excellent surface finish, flexibility, as well as strength and hardness”, says Christian Lönne, CEO at Digital Metal. “This alloy is very stable during heat treatments, which allows for tailoring of the final material properties through various heat treatments after sintering.”

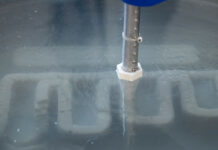

The launch of this tool steel alloy follows the recent launch of the software upgrade that triples the print speed of Digital Metal® ‘s 3D Printer. Last but not least, it somehow contributes to making the DM P2500 ideal for serial production of small complex metal components.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com