Researchers from TU Delft (The Netherlands) have always been looking for a hybrid meta-biomaterial that can promote bone growth. With the use of a 3D printer and existing biomaterials, they recently developed a meta-implant that combines a conventional meta-biomaterial with an auxetic meta-biomaterial.

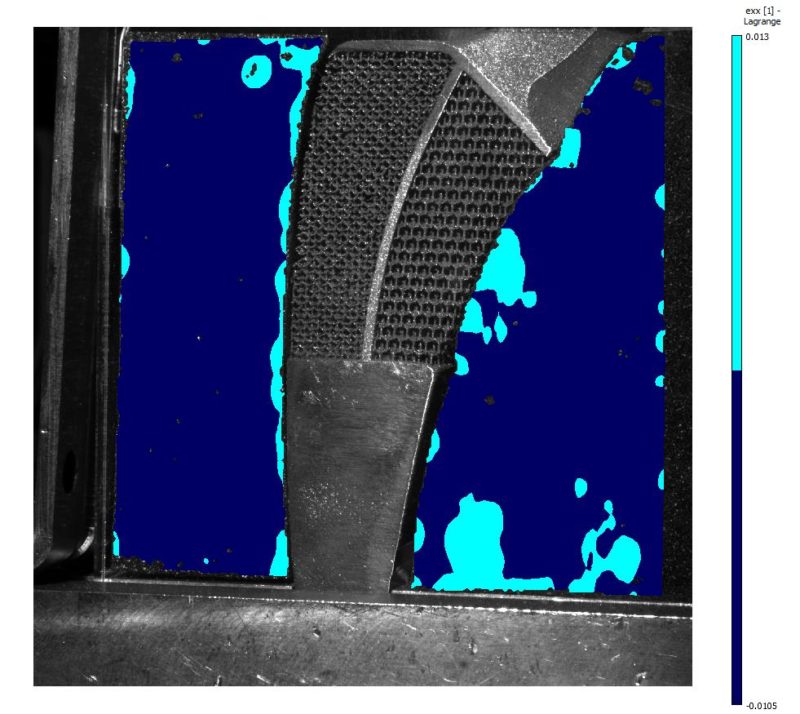

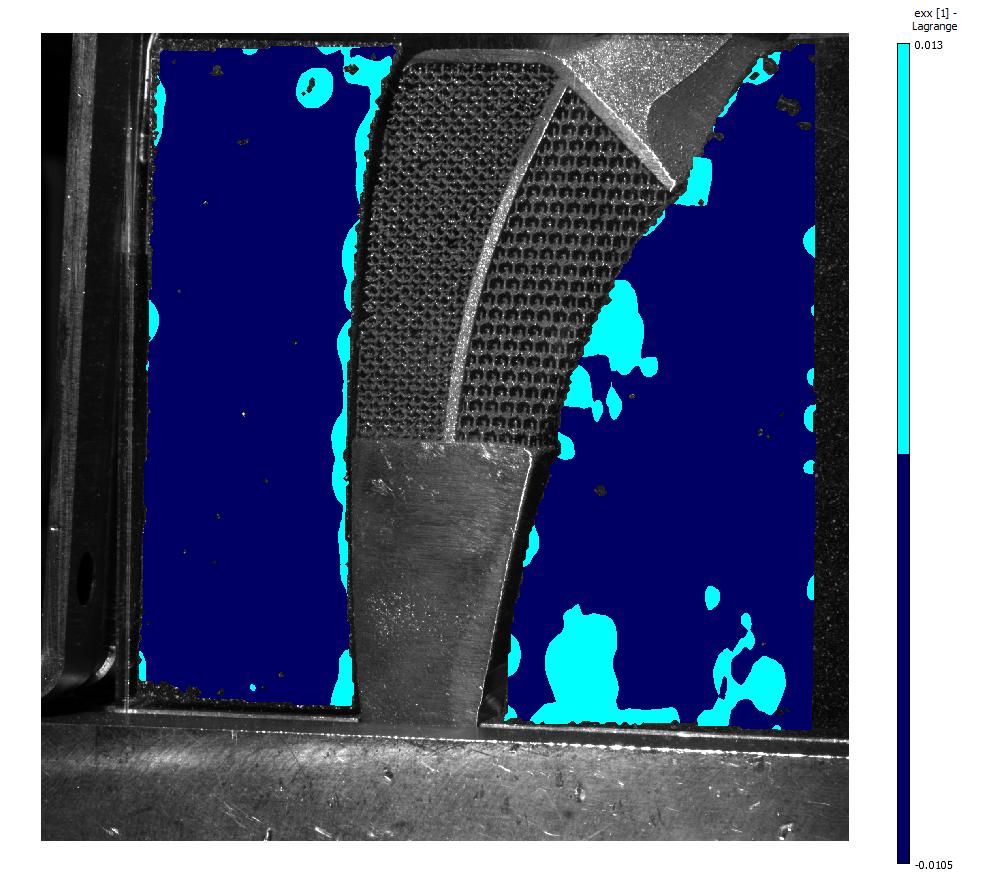

Researches demonstrate that auxetics (type of materials) have a negative Poisson’s ratio: when stretched, they become thicker perpendicular to the applied force. Therefore, the material can be applied in hip implants to ensure their long-term fixation.

What inspired Delft’s researchers

In two years, the rate of hip prostheses around the world will certainly rise up to 2.5 million a year. The use of current technology (conventional technology) will no longer allow a long-term fixation. That’s why TU Delft Professor Amir Zadpoor, in charge with the research, was looking for ways to prevent implant loosening. According to the professor, the auxetic meta-biomaterial is the ideal solution to ensure a long-term fixation.

‘Auxetic meta-biomaterial, designed using simple geometry and printed in titanium, displays the unique mechanical property of expanding when put under pressure. This makes it ideal for use alongside materials that do the opposite’, explains Zadpoor. ‘When someone with a hip implant walks, the prosthesis is subjected to various forces. If too much pressure develops on one side of the prosthesis, it can become detached from the bone, which is extremely undesirable’.

However, future researches must still be carried out in order to discover how bone-like material (special foam with the mechanical properties of bone) can be used to develop better implants.

3D technology will therefore be helpful since a phased introduction starting with 3D measurements of this implant in patients will be necessary in order to guarantee the safe improvement of quality for patients.

The whole research can be read in the scientific journal Materials Horizons on 2 January 2018.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!