Among the challenges that can slow down the health and productivity of dairy cows, there is subclinical hypocalcemia (SCH). It occurs when calcium levels in the blood fall below normal without overt symptoms, affecting nearly half of mature dairy cows and a quarter of first-time calvers.

This condition compromises muscle and nerve function, leading to reduced feed intake, lower milk production, and increased susceptibility to other diseases.

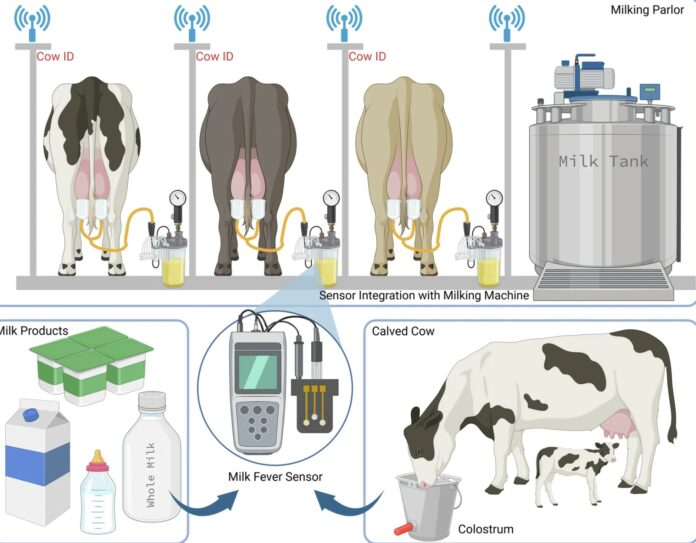

To address this issue, a research team from Virginia Tech, developed a compact, and highly sensitive sensor capable of detecting calcium (Ca²⁺) and phosphate (P) levels directly in milk samples. In general, farmers use commercial analyzers or subjective assessments based on visible symptoms like weakness or difficulty standing to detect SCH.

While we don’t know yet what 3D printing technology has been used, we know the technology has helped to develop a sensor with intricate microstructures, and a wrinkled surface created using poly(3-octyl-thiophene) (POT), a solid-contact ion-to-electron transducer.

These design elements enhance the surface area, enabling rapid and highly accurate detection of milk ions. A diagnostic device that can identify SCH in as little as 10 seconds with attomolar sensitivity.

Farmers can now test milk samples on-site, eliminating the need for invasive blood tests or transporting samples to labs.

Thanks to 3D printing, it was possible to fabricate sensors without using expensive clean room facilities for a range of biomarkers in milk, paving the way for comprehensive livestock health monitoring.

The full study is available here.

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.