Copper3D has announced today a new reseller agreement that will enable them to increase the availability of their antibacterial 3D Printing filament in Europe. The US-based company has signed 3D GBIRE as a new distributor for the UK and Ireland regions.

The antibacterial 3D printing filament has been tested last year by several experts. The material is a PLA that integrates a patented additive based on copper nanoparticles and other elements. Called PLACTIVETM, its properties enable to remove a set of microorganisms.

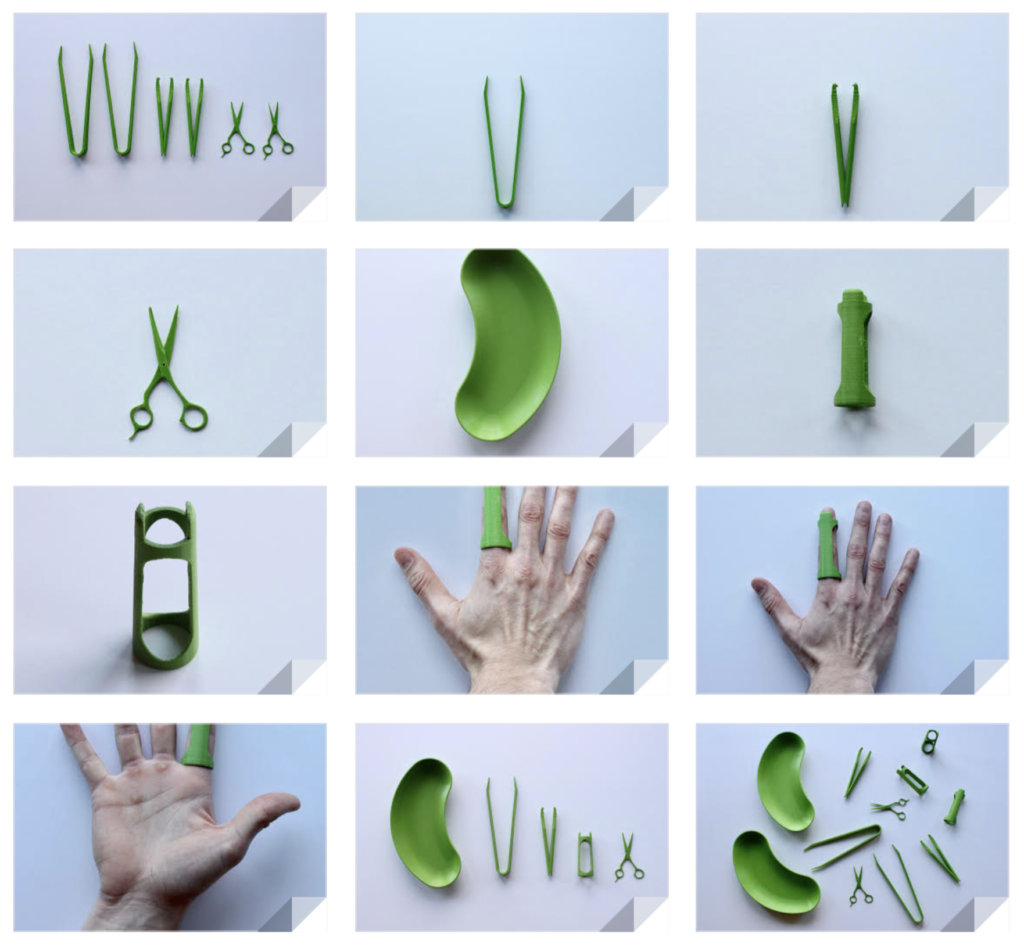

In a press release, Copper3D explained that what led to this creation is the fact that more than 40% of amputees suffer some type of dermic disorders due to the use of their 3D printed prostheses. This phenomenon is also observed in non-amputee patients who use 3D printed orthoses.

Furthermore, such type of dermic disorders is often the result of porous materials, direct contact with the skin or even complex geometries of the prosthetics and orthotics that do not enable a thorough cleaning.

Even though, the medical industry seems to be the first one that may take advantage of this material, it goes without saying that other industries may benefit from this antibacterial solution. As a matter of fact, who wouldn’t want a material that could protect users’ health?

As far as 3D GBIRE is concerned, it should be noted that “the Medical and humanitarian applications of FDM 3D printing have always been a driving force for 3DGBIRE to be involved in the 3D Industry. 3DGBIRE have worked extensively with hospitals and medical organizations thought the UK on projects using FDM printers. Being able to further the Medical application potential through the use of these revolutionary new materials is a groundbreaking achievement and 3DGBIRE are thrilled to be partnering with Copper 3D and to be joining the Antimicrobial 3D Printing Ecosystem. Being able to contribute towards the advancement of patient care and the improvement of the medical recovery process is something we are all extremely proud to be part of and we can’t wait to make these revolutionary materials available to more markets than ever before.”

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter

Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com