ToffeeX, a startup that develops an AI-powered software for physics-driven generative design, has developed a design framework that captures thermo-fluid behavior without resorting to CFD.

The company has worked on this project in collaboration with Imperial College London, and the University of Wolverhampton. Multiscale modeling offers a computationally efficient solution to the challenges posed by traditional CFD. It models complex systems by solving a series of decoupled smaller systems, which are then assembled to replicate the full behavior accurately. The decoupling dramatically reduces computation time while maintaining high resolution.

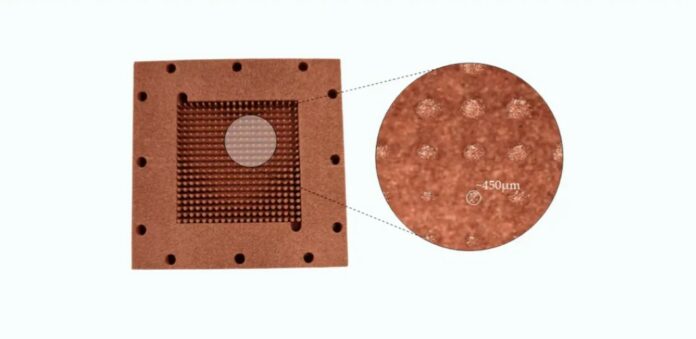

In parallel, the University of Wolverhampton has utilized its EOS M290 LaserPowder Bed Fusion (L-PBF) technology, deploying a 400W laser to manufacture these designs in high purity copper. Known for its high thermal conductivity, copper has traditionally presented challenges in 3D printing due to its reflective properties. However, this partnership has overcome those obstacles, producing copper heat sinks with enhanced precision and durability, showcasing the potential of L-PBF technologies.

Professor Arun Arjunan, director of the university’s Elite Centre for Manufacturing Skills (ECMS) and Centre for Engineering Innovation and Research (CEIR) said: “Working with ToffeeX, and Imperial College London pushing the boundaries of L-PBF copper printing and heat sink design highlights the potential of additive manufacturing and thermal management. By combining our expertise in advanced materials and 3D printing technologies, we will continue to develop innovative solutions that meet the growing demand for efficient thermal management systems across various industries.”

Integrating multiscale modeling with copper 3D printing enables to improve heat transfer performance while reducing energy demands. By enhancing pure copper designs, engineers can achieve superior thermal efficiency and significantly lower CO2 emissions, advancing the transition to a more sustainable future.

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.