Conflux Technology, a company that leverages Additive Manufacturing (AM) for thermal management and fluid applications, closed a Series B round of $11 million.

Breakthrough Victoria led the round with contributions from AM Ventures and Acorn Capital. Headquartered in Melbourne, Conflux Technology specializes in manufacturing high-performance heat exchangers for motorsport, defense, aerospace, and energy industries. AM helps the company build a heat exchanger as a single part, saving time, materials, and energy.

Michael Fuller, the Founder & CEO of Conflux Technology reveals, “At Conflux Technology we pride ourselves on providing efficiency through heat transfer performance and reducing weight at the heart of the world’s devices. With this additional funding and support, we will continue to advance our products and expand to support our customers globally. Next-gen aviation is a key industry for us, and we will demonstrate our commitment to helping innovators in this space. We’re proud to assist customers like Odys Aviation by providing them with the tools they need to drive advancements in sustainable aviation and power their aircraft efficiently.“

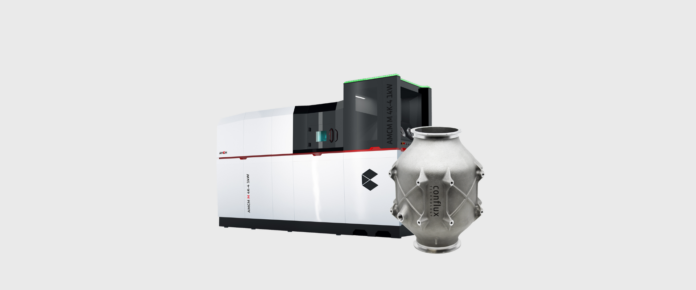

Key development areas include Conflux Production Systems (CPS) enhancement, a modern solution for building 3D printed heat exchangers. It replaces traditional heat exchanger manufacturing plants by automating the process for scalable and repeatable outcomes.

The funding will also help scale up Conflux operations and expand its global footprint by growing its customer base in North America, Europe, and Asia. Conflux will strengthen its workforce, improve supply chain dynamics, and continue R&D efforts by pushing thermal efficiency limits.

Conflux is also contributing to innovation in green aviation. It is working with Odys Aviation to develop next-generation VTOL aircraft, which reduces fuel consumption by more than 40%. These projects are a testament to the company’s commitment to supporting key industries in their journey towards greener technologies.

Combining Odys’ expertise in hybrid-electric propulsion systems and the manufacturing solutions from Conflux, the firm plans to build a heat recuperator turbogenerator solution that can easily integrate into an existing aerospace turbine reducing the weight and 40% of fuel consumption to gain maximum efficiency.

This solution will be integrated into Odys Aviation’s 21-foot wingspan ‘Laila’ aircraft, a plane created with multiple cargo specifications to achieve a target range of 450 km with payloads up to 130 pounds.

The CEO, and Co-Founder of Odys, James Dorris explains, “Conflux’s additive manufacturing and metal 3D printing technology erase traditional design barriers, allowing us to bring geometrically complex and performance-optimized recuperator designs to life resulting in longer-range and higher-payload aircraft. We’re excited to collaborate with Conflux’s team to redefine the capabilities of VTOL UAS systems.”

Author: Nagarjun M

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.