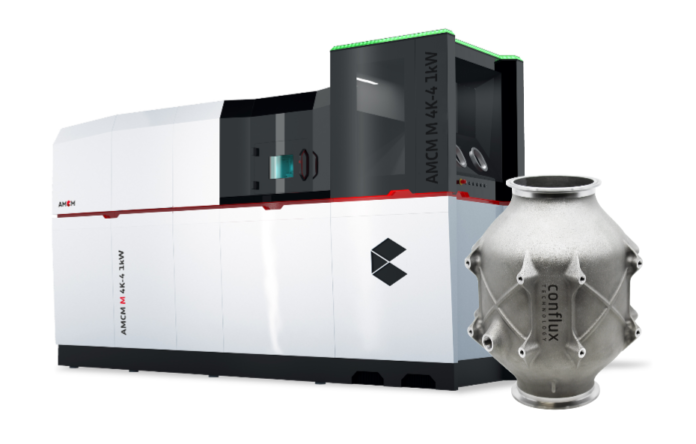

The Additive Manufacturing (AM) industry is at a crucial junction in history where the technology itself has been used to create parts for a 3D printer. Today, the story highlights metal AM heat transfer technology solutions provider Conflux Technology which is entering the serial production of heat exchangers for the AMCM M 4K 3D printers.

The machine is manufactured by Additive Manufacturing Customized Machines (short for AMCM GmbH), a developer of customized metal 3D printers based on EOS technology.

Now, the new upgraded AMCM M4K 3D printer has a thermal management system whose key aspect is the gas-liquid heat exchanger. Using the Conflux heat exchanger, the argon gas temperature was reduced by several degrees Celsius, making AMCM M4K 3D printer operate at high efficiency with longer build times and high-speed processing. This is essential for large build volumes.

The Conflux heat exchanger met the pressure drop and temperature targets set by the company and occupied 7% of the packaging volume and reduced the pressure drop.

The case study of developing the argon gas heat exchanger for AMCM 3D Printers revealed three objectives set by Conflux:

- Reduction of argon gas temperature to 25°C with minimal pressure drop: This feature improved the build time and quality, pushing the performance of the M4K platform.

- Packaging volume reduction: The company reduced the overall package volume to 93% of the previous system while bettering the performance

- Monolithic build: Conflux used 3D-printed parts to make supporting ducts on both ends of the heat exchanger, which kept the piece price of each product within AMCM’s target range. This allows for a simplification of installation and maintenance processes for AMCM M4 systems.

The Managing Director of AMCM, Martin Bullemer said: “Embedding Conflux’s additive manufactured heat transfer technology enables us to continue pushing the boundaries of what our 3D metal printing machines can do”.

The company will build on the success of the M4K system and use Conflux heat exchangers for its M8K system which has a build volume of 800 x 800 x 1200 mm.

Meanwhile, the CEO of Conflux Technology Michael Fuller said: “Bringing our heat exchanger expertise to the additive manufacturing machine tool industry has been a long-held ambition of mine and is now realized with the successful adaptation of our Conflux Core™ technology into AMCM’s premier platform”.

Conflux Technology will be displaying their argon gas heat exchanger at Formnext 2023 in Booth E45 hall 11.1 from November 7 to November 10.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com