Colibrium Additive – a GE Aerospace company is one of the companies whose attendance was expected at RAPID+TCT 2024. For those who do not know, this is their first public appearance ever since GE Additive announced its rebranding. One question we had in mind was: are they going to live up to that new vision?

So far, when we look at the range of product launches and product upgrades showcased on the show, there is no doubt they are on the right path in this journey.

In the hardware segment

Remember that the company has been talking a lot about its highly anticipated GE Additive’s binder jet 3D printing solution – a solution that it has been developing during the past six years? Well, the wait is over as we received confirmation that this new industrial 3D printer is now commercially available.

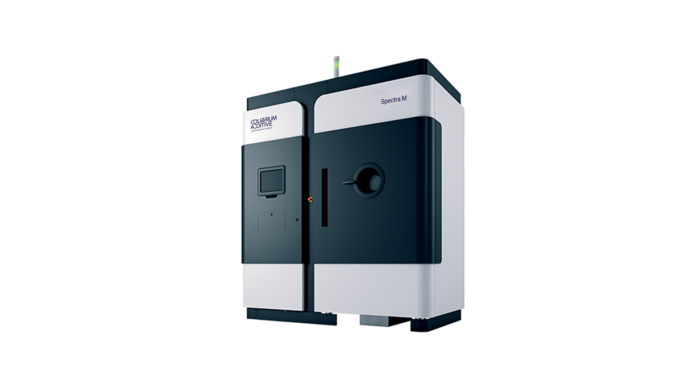

In its portfolio of industrial 3D printers, AM users could also benefit from the Spectra M, a new addition to the Spectra portfolio. Designed for users who are looking to achieve smaller build volumes, the Spectra M would especially attract medical and orthopedic implant manufacturers.

“Having the largest installed base of highly experienced, long-standing users provides invaluable insight and help is constantly evolving our portfolio to provide EB-PBF technologies that fulfil their specific requirements as they continue to scale their additive manufacturing operations. Spectra M is in direct response to constant dialogue with our customers, particularly those additive super users in the orthopedic implant industry,” said Oscar Angervall, senior product manager, Colibrium Additive.

Colibrium Additive said the 3D printer is equipped with EBMControl 6.4, also launched at RAPID + TCT 24, and is fully compatible with Point Melt, Powder Supports, and Plate Free technology. Depending on their application, customers can choose between a high productivity theme or an advanced Point Melt-based process theme, to enable truly support-free printing without compromising surface roughness or mechanical properties.

With Ti6Al4V Grade 5 and Ti6Al4V Grade 23 as first materials compatible with the system, other key specifications of the machine include a build envelope of Ø270 x 430 mm and a beam power of 4.5 Kw.

Point Melt, Powder Supports, and Plate Free technology

Apart from the new Spectra M printer, users of the Spectra L 3D printer can also benefit from these new upgrades of the electron beam melting (EB-PBF) software.

Point Melt technology, melts metal powder through small “points” instead of lines, enabling a more accurate temperature as well as reducing temperature gradients through the printing of a part. Offering excellent isotropic material properties independent of build direction, including a significant increase in yield strength, Point Melt allows for freedom of orientation. Parts made with Point Melt demonstrate excellent surface roughness, on par with laser powder bed fusion, a press communication explains.

“Controlled with adaptive software algorithms, Point Melt marks a step change in melt strategy. Metal parts can benefit from a reduction of support needed to build overhangs and an improved surface quality,” said Oscar Angervall, senior product manager, Colibrium Additive.

Powder Supports are a new solution for supporting parts during the build. The enlarged process window enabled by Point Melt functionalities significantly reduces or eliminates the number of support structures needed, while Powder Supports retain the excellent dimensional accuracy of line melt with supports. For customers, the new tool aims to reduces post-processing costs.

Plate Free is an alternative to conventional ‘Start Plate Heating’ and offers a more cost-effective, hands-off way to start a build. During the Plate Free start, powder is gradually sintered to a point where parts can be built on top, bringing a range of advantages around quality and cost. These include:

- Decreased machine turn-around times and less operator dependencies.

- Reduced risk of contamination, longer cathode lifetime.

- The possibility to start several builds per machine turnaround.

- Eliminating one heavy, spacious, and expensive consumable.

In addition, Plate Free versus Start Plate Heating is set with themes and, therefore requires no effort to swap between builds.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com