Coherent Corp., an expert in ceramics and metal matrix composites, has developed an additive manufacturing process capable of producing advanced ceramic components for high-performance thermal management applications, such as semiconductor capital equipment.

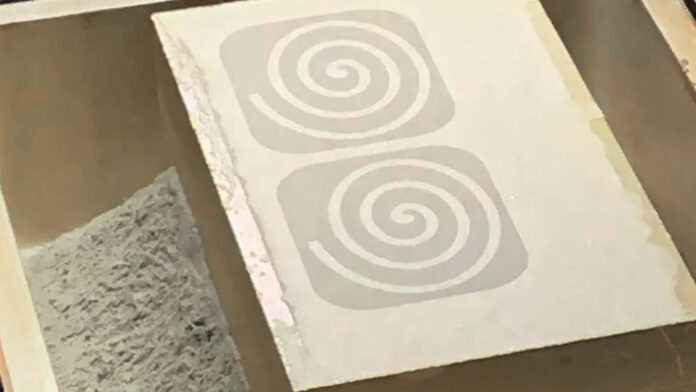

Severe shortages of integrated circuits based on leading-edge nodes have spurred massive investments worldwide in the buildout of semiconductor manufacturing facilities equipped with the most advanced semiconductor capital equipment. Coherent has successfully developed proprietary materials and technologies that enable ceramic components produced with its additive manufacturing process to match those produced with its existing molding process in their mechanical and thermal properties. Ceramic components manufactured with the new additive manufacturing process can now be precision-machined using laser-based techniques, including those available at Coherent. These are critical for next-generation semiconductor capital equipment. Additive manufacturing is superior to molding in process capability, yield, and throughput. It requires no retooling time between components, which minimizes lead times and waste. As such, additive manufacturing is ideal for Industry 4.0 factories that are designed for resilient and flexible scaling.

Additive Talks: How does Additive Manufacturing serve Electrification?

“Ceramic additive manufacturing enables components that are lighter and with entirely new geometries, which are required for next-generation semiconductor capital equipment designs. Until now, these components were lower in quality and precision compared with molded ceramic components. With this new breakthrough, our customers will benefit from the best of both worlds,” said Steve Rummel, Senior VP, Engineered Materials and Laser Optics Business Unit. “We’re moving quickly to establish a new ceramic additive manufacturing line in Temecula, California. We’ve also defined with our customers a strategic roadmap to broaden our additive manufacturing capabilities, beyond ceramics, to a wider range of materials, including metals.”

Ceramic components produced with the proprietary additive manufacturing process from Coherent can achieve a state-of-the-art elastic modulus of 365 GPa and a flexural strength of 290 MPa. They are ideal for a wide range of semiconductor equipment, including in photolithography, deposition, and etching. They are also a great solution for advanced packaging components with integrated cooling channels, for high-performance computer processors such as CPUs and GPUs.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com