The food industry is probably one of the sectors where 3D printing still has to prove itself. However, the innovations within this domain are as inspiring as cooking recipes.

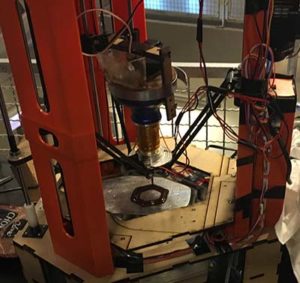

At the University of Lund, students suprise the public – using 3D printing to print chocolate on water. Their challenge was to develop the 3D printer’s capability into rapidly printing chocolate.

3D Printing and Chocolate

A good number of people love chocolate in its various forms, but as part of this experience, the rapid solidification of chocolate had to be made for the layer to be printed.

Some students have used conventional methods in order to solidify the chocolate. The Peltier device was used to create cold air or a cold printed plate. However, instead of using the traditional method, a group of students proposed to directly test the printing of chocolate on cold water.

Advantage?

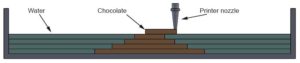

This enables “overhangs to be printed without support material because the overhangs could float on the surface of the water.”

The group further explains that the idea was “first printing a layer of chocolate on the bottom of the print container, and then flooding that layer with a layer of water of the same thickness, which very quickly solidifies the chocolate. Water surface tensions prevents the water from flowing onto the chocolate. Then the next layer is printed on top of the first layer of chocolate and, if necessary, can overlap/float on top of the previously added layer of water.”

Improvements?

The students are only in the beginning stages and still have much to learn in regards to familiarizing themselves with the numeric prototypes such as: CAD, 3D Printing, laser and water jet cutting, CNC machining, etc.

The Next Step?

The next step consists of developing an entire machine that prints in a reliable manner successfully from the first try.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!