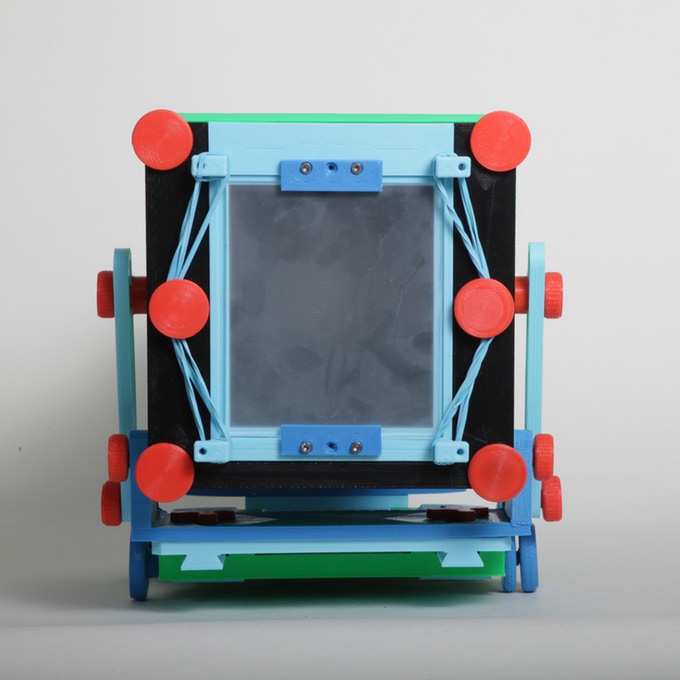

This is the story of Ethan Moses, a maker of cameras, in general out of wood and metal. He decided to redefine the way he builds when he got his 3D printer. That’s how he gave life to Cameradactyl, a 3D printed 4×5 field camera that he designed for friends and fellow photographers.

The manufacturing process

The manufacturing process

The maker tried to retain as much functionality and durability as possible with entirely plastic components. From what we can see in the video, the camera definitely looks like an entry level one whose professional attributes haven’t been left apart.

As far as technical details are concerned, Ethan explained that “this camera is based on a classic field camera design and keeps many professional camera movements. It has rack and pinion geared focusing rails for both the front and back standards, front swings, tilts, rise and fall, and rear swings and tilts. The bellows accommodates lenses from about 90mm to 300mm. “I like using 150mm and 210mm normal lenses; they allow for a good range of movements, and have the angle of view I prefer working with in this format”, adds the maker.

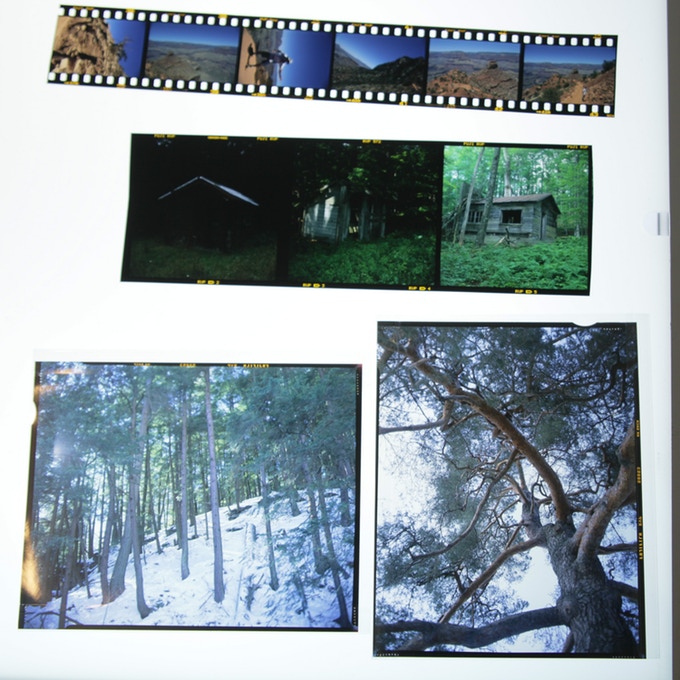

However, for those who did not get used with large format cameras and accessories, it should be noted that there is no lens or film holders in Ethan’s camera. Photographers will need at least one of each to use the device. And the maker recommends the user to buy his on a distributor. A 4×5 is recommended to create very high resolution, tack sharp corner to corner images, or extremely shallow depth of field.

However, for those who did not get used with large format cameras and accessories, it should be noted that there is no lens or film holders in Ethan’s camera. Photographers will need at least one of each to use the device. And the maker recommends the user to buy his on a distributor. A 4×5 is recommended to create very high resolution, tack sharp corner to corner images, or extremely shallow depth of field.

As far as 3D printing is concerned, this fabrication process enables to offer custom color schemes for each camera. However, the lens board and film back are always printed in black, but there are 10-part groups that can be printed in other colors. Ethan explained for instance that he is currently “printing in eight colors, which when raised to the 10th power (# of print/part groups) allows for 1,073,741,824 possible color combinations, before choosing a bellows covering fabric.”

For further information, follow us on our social media and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com