With the goal to repair and maintain operation of public transport, Italian engineering company 3DnA S.r.l has recently demonstrated how 3D printing might be a good production candidate to ensure the fabrication of spare parts.

As part of a collaboration with Neapolitan public transport company Azienda Napoletana Mobilità S.p.A (ANM), a company that manages the entire public transportation network in Napoli, which includes the city’s famed trolleybuses, 3DnA S.r.l needed to replace many of the buses’ trolley heads were broken, no longer usable and obsolete on the market. This part is a very pivotal one as it connects the aerial power supply line to the trolleybus. The part’s obsolescence left the entire fleet at risk in the event of repeat breakages.

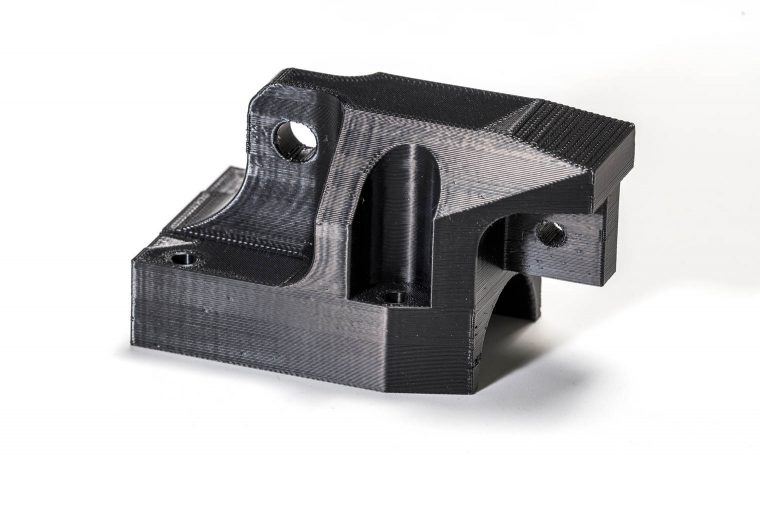

To address this issue, 3DnA S.r.l relied on a Stratasys F900® 3D printer – a 3D printer that has already enabled many companies in the industry to achieve jigs and fixtures, functional prototypes or production parts. Combined with the acknowledged Stratasys ULTEM™ 9085 resin, the team at 3DnA got the structural support required for the rigors of everyday use, while also meeting the necessary electrical insulation standards. The manufacturing process therefore consists in 3D scanning the part, redesigning so that in the event of damage, only a small component of the trolley head would need replacing – not the entire part, as previously and then producing it. The F900 served for the production of the exterior casing that connects the trolley head to the overhead wires.

“Creating the trolley heads with traditional manufacturing processes would have taken up to 12 months, resulting in a lengthy downtime for the vehicle that is simply not an option,” explains Alessandro Manzo, 3DnA’s General Director. “Using our F900, we were able to produce and deliver about 20 of the most critical parts of the trolley head in two weeks, enabling ANM to eliminate further risk of downtime to its fleet and ensure reliable transportation for the three million citizens of Naples. Overall, having this level of production flexibility is extremely important to ANM, as it can now order parts based on actual needs as opposed to warehousing large quantities of costly inventory.”

“The part cannot conduct electricity, so having this material is essential. In addition, ULTEMTM 9085 resin provides us three key criteria required for end-use transportation applications: excellent heat resistance with a heat deflection temperature of 153°C, it is a flame-retardant thermoplastic, and offers a very high strength-to-weight ratio”, he adds.

The new trolley head is made up of a core metal structure. Such has been the impact that it has now become the part of choice for the whole fleet.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com