Breton, an Italian, privately held company acknowledged for the development of high production machining centers, lines and stand-alone machines for processing materials (natural stone, marble, granite, quartz, ceramic, heavy clay, mineral surface, resins and foams, polymers, and metals) debuted in the Additive Manufacturing industry two years ago with the launch of Breton Genesi, the range of 3D printers for large-scale production on thermoplastic materials dedicated to the Additive Manufacturing industry (LSAM).

In just two years and thanks to its deep expertise in machinery and engineering, the company has developed a complete ecosystem that can help any company – whatever the industry it is operating in – adopt AM, from design to end of product.

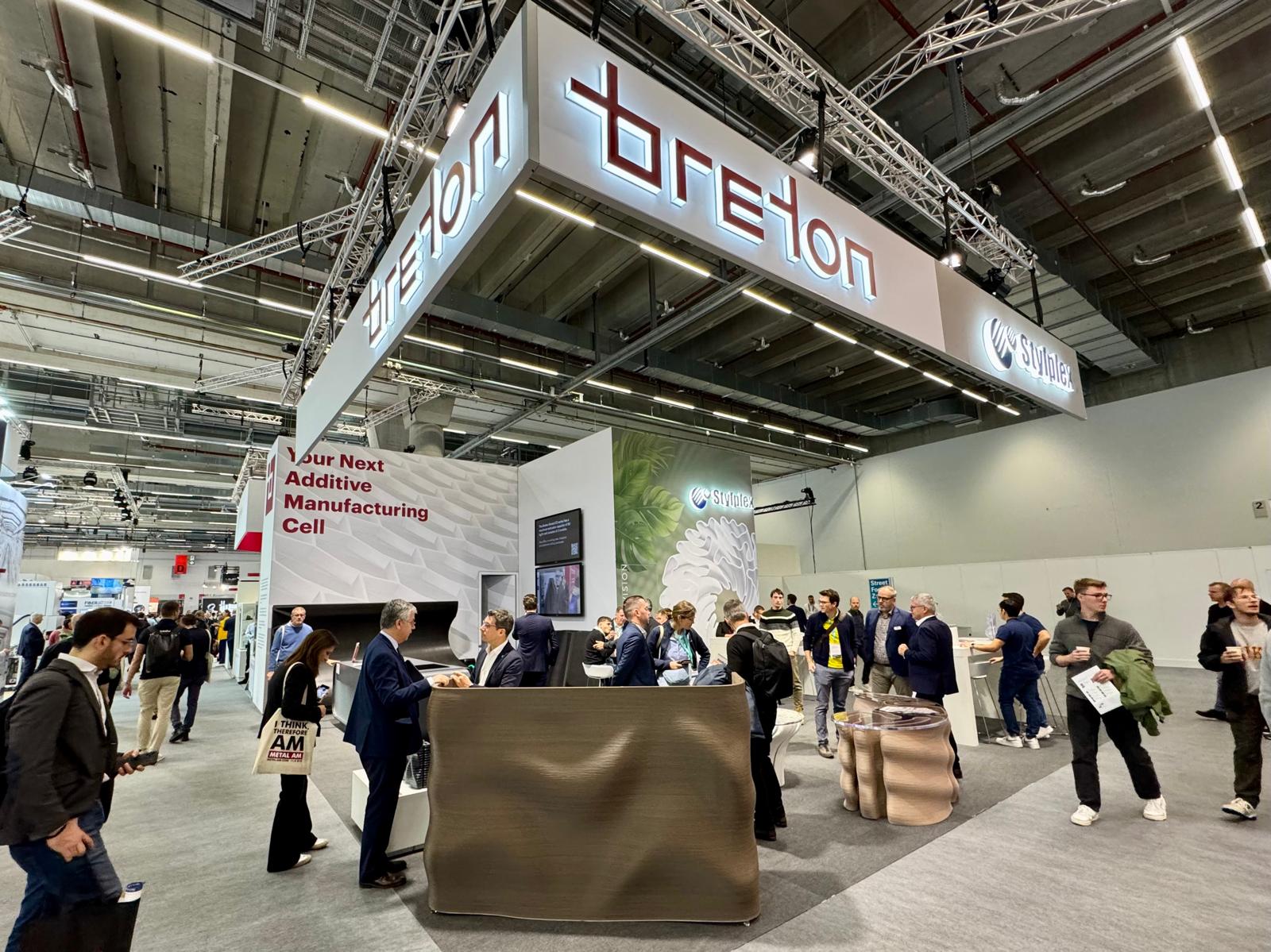

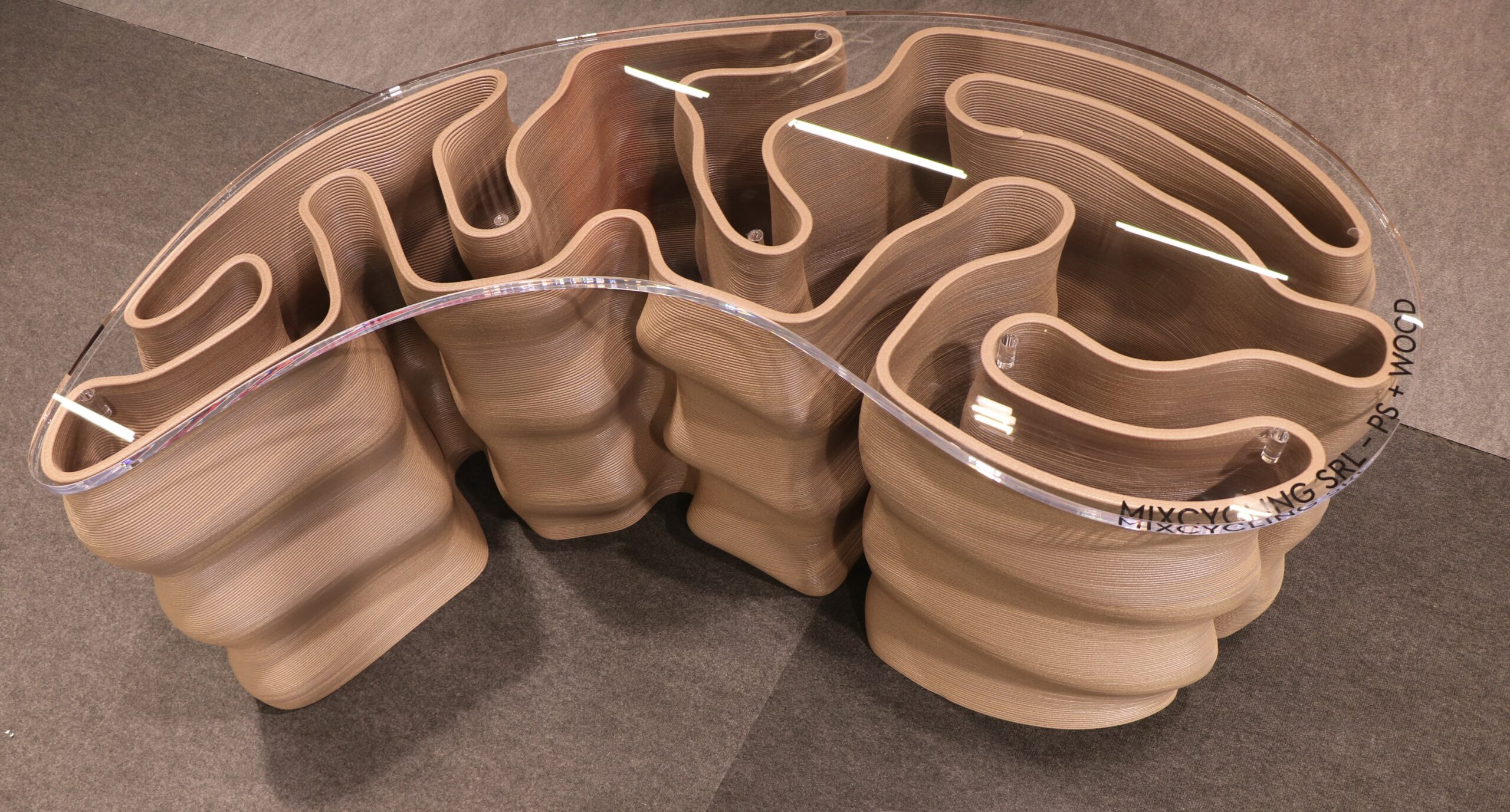

We hope to share further insights into each product of this ecosystem in the upcoming months. In the meantime, we can’t help but recall how visitors at Formnext 2024 were attracted to the company’s booth by a chef cooking on the world’s first 3D printed kitchen Island (KiS) of 3.000 x 1.000 x 900 mm. However, they stayed to discover how Stylplex, an architectural and design firm with no experience in large-format AM, has been able to make AM another core part of its business thanks to Breton.

Breton makes its machines and expertise available to companies who want to join the Additive Manufacturing world becoming a Breton Authorized Additive Manufacturing Center. If you think your company could be the next Breton Authorized Additive Manufacturing center, you can apply for it here.

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.